Analysis of Failure Causes of Tees in Inlet Pipelines of Hydrocracking Pumps (Part Two)

Posted: 11/27/2021 04:11:00 Hits: 3

4. Scanning electron microscopy analysis

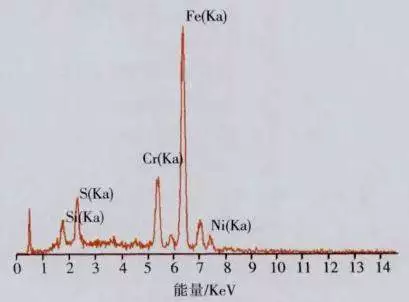

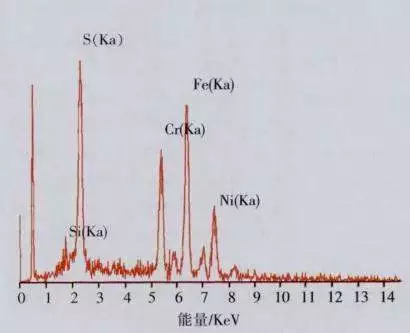

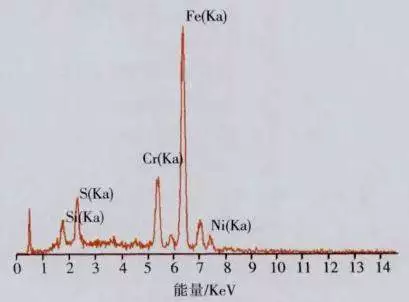

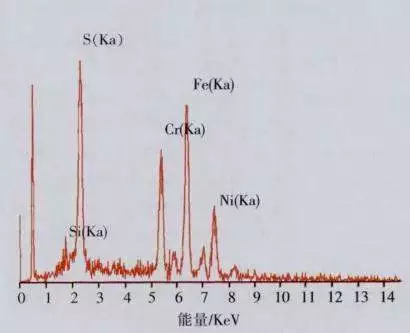

Cut the tee along the crack's propagation direction and performed scanning electron microscopy analysis. The microscopic morphology of the fracture is shown in Figure 6, and the propagation direction of the crack was from the inner wall to the outer wall. There were corrosion pits at the edge of the inner wall of the fracture. This corrosion pit induced cracks on the inner wall, as shown in Figure 7. Further scanning electron microscopy analysis was performed on the inner wall of the fracture, and many cracks were found near the inner wall of the fracture. The cracks started from the corrosion pit and expanded along the inner wall; there were many connected corrosion pits on the path of the crack propagation on the inner surface, as shown in Figure 8. After energy spectrum analysis of the corrosion products on the fracture surface, it is found that the main components of the corrosion products were sulfides, as shown in Figure 9. After the energy spectrum analysis of the corrosion products in the corrosion pits at the crack part of the inner wall, it is found that the corrosion products in the corrosion pits were mainly sulfides, and the content is relatively high, as shown in Figure 10.

5. Failure analysis

The chemical composition of the tee met the chemical composition of 0CrI8Ni9 required in the standard, and the chemical composition was qualified.

Figure 6 Microscopic morphology of the fracture

Figure 7 Corrosion pits on the fracture

Figure 8 Corrosion pits and cracks on the inner wall of the tee

From the results of the metallographic structure analysis of the tee, it can be seen that the austenite grain boundaries were not obvious, and there was no twin crystal austenite produced by the solution treatment. In addition, there were deformed slip lines in the austenite grains, and σ phase was precipitated at the austenite and ferrite grain boundaries, indicating that the stainless steel tee has been formed by hot pressing and has not been subjected to solution treatment after hot pressing. In the hot pressing process of the tee, the hot pressing temperature was from 600 to 900℃, and when the cooling rate was slow, carbides containing chromium and σ phases containing rich chromium would be precipitated, resulting in chromium depletion at the austenite and ferrite grain boundaries. The appearance of σ phase containing rich chromium reduced the corrosion fatigue resistance of stainless steel. Under the action of the extremely active chloride ion in the corrosive medium, corrosion occurred in the chromium-depleted area around the σ phase containing rich chromium, resulting in corrosion pits. When the hydrogen sulfide content was high, microcracks would be generated under the action of stress corrosion of hydrogen sulfide, and the microcracks would gradually expand and cause the tee to crack and leak. The scanning electron microscope analysis showed that there were many cracks on the inner wall of the tee, and the source of the cracks was all at the corrosion pit. The main component of the corrosion product on the surface of the corrosion pit was sulfide, and the content was very high. The corrosion product on the surface of the fracture was mainly composed of sulfide, and the content was high; the fracture was brittle fracture. The cracking of the tee has the characteristics of hydrogen sulfide stress corrosion cracking.

Figure 9 Energy spectrum analysis of corrosion products on the fracture's surface

Figure 10 Energy spectrum analysis results of corrosion pits on the inner wall of the tee

The manufacturing process was not strictly implemented for the stainless steel tee in the manufacturing process, which led to the precipitation of σ phase in the metallographic structure, and a solution treatment was not performed after manufacturing, reducing the corrosion resistance of the material. Corrosion pits were generated under the long-term action of chloride ions in corrosive media. The appearance of corrosion pits became the source of induced cracks. Stress corrosion cracks easily generated in the wet hydrogen sulfide environment. After the overhaul, the hydrogen sulfide content increased sharply, approximately 10 times higher than that in the past. The corrosiveness of the medium increased sharply, which intensified the susceptibility of stress corrosion of hydrogen sulfide. At the same time, since the temperature of the medium was 30 to 40℃, it was also within the sensitive temperature range of hydrogen sulfide's stress corrosion. The appearance of corrosion pits was the source of induced cracks. The sharp increase of hydrogen sulfide content accelerated the hydrogen sulfide stress corrosion rate and cracking rate of cracks, which caused the stainless steel tee to crack in a short time.

6. Conclusion

(1) The chemical composition of the tee met the chemical composition of 0Cr18Ni9 required in the standard, and the chemical composition was qualified.

(2) The cracking of the stainless steel tee was stress corrosion cracking under the combined action of chloride ions and hydrogen sulfide in a wet environment.

(3) The main cause of cracking was that the mass concentration of hydrogen sulfide has increased from less than 1 g/L in the past to 7 to 10 g/L now.

The mass concentration of the harmful substance which was hydrogen sulfide has increased sharply, causing the corrosiveness of the medium to increase sharply. At the same time, the presence of chloride ions in the medium accelerated the hydrogen sulfide's stress corrosion rate. The manufacturing process of the stainless steel tee wasn't strictly implemented in the manufacturing process, which led to the precipitation of σ phase in the metallographic structure. Not undergoing a solution treatment after manufacturing reduced the corrosion resistance of the material, and corrosion pits were generated under the action of chloride ions in the corrosive medium for a long time and became the source of induced cracks. The joint action of the two caused the cracking of the stainless steel tee.

7. Recommendations

(1) Control and reduce the chloride ion content in the material.

(2) Inspect stainless steel pipe fittings in the same batch and perform regular inspections.

(3) Use gas detectors to strengthen on-site inspections to ensure safe operation.

(4) Control the quality of stainless steel pipe fittings. It is recommended to choose better materials when conditions permit.

Cut the tee along the crack's propagation direction and performed scanning electron microscopy analysis. The microscopic morphology of the fracture is shown in Figure 6, and the propagation direction of the crack was from the inner wall to the outer wall. There were corrosion pits at the edge of the inner wall of the fracture. This corrosion pit induced cracks on the inner wall, as shown in Figure 7. Further scanning electron microscopy analysis was performed on the inner wall of the fracture, and many cracks were found near the inner wall of the fracture. The cracks started from the corrosion pit and expanded along the inner wall; there were many connected corrosion pits on the path of the crack propagation on the inner surface, as shown in Figure 8. After energy spectrum analysis of the corrosion products on the fracture surface, it is found that the main components of the corrosion products were sulfides, as shown in Figure 9. After the energy spectrum analysis of the corrosion products in the corrosion pits at the crack part of the inner wall, it is found that the corrosion products in the corrosion pits were mainly sulfides, and the content is relatively high, as shown in Figure 10.

5. Failure analysis

The chemical composition of the tee met the chemical composition of 0CrI8Ni9 required in the standard, and the chemical composition was qualified.

Figure 6 Microscopic morphology of the fracture

Figure 7 Corrosion pits on the fracture

Figure 8 Corrosion pits and cracks on the inner wall of the tee

From the results of the metallographic structure analysis of the tee, it can be seen that the austenite grain boundaries were not obvious, and there was no twin crystal austenite produced by the solution treatment. In addition, there were deformed slip lines in the austenite grains, and σ phase was precipitated at the austenite and ferrite grain boundaries, indicating that the stainless steel tee has been formed by hot pressing and has not been subjected to solution treatment after hot pressing. In the hot pressing process of the tee, the hot pressing temperature was from 600 to 900℃, and when the cooling rate was slow, carbides containing chromium and σ phases containing rich chromium would be precipitated, resulting in chromium depletion at the austenite and ferrite grain boundaries. The appearance of σ phase containing rich chromium reduced the corrosion fatigue resistance of stainless steel. Under the action of the extremely active chloride ion in the corrosive medium, corrosion occurred in the chromium-depleted area around the σ phase containing rich chromium, resulting in corrosion pits. When the hydrogen sulfide content was high, microcracks would be generated under the action of stress corrosion of hydrogen sulfide, and the microcracks would gradually expand and cause the tee to crack and leak. The scanning electron microscope analysis showed that there were many cracks on the inner wall of the tee, and the source of the cracks was all at the corrosion pit. The main component of the corrosion product on the surface of the corrosion pit was sulfide, and the content was very high. The corrosion product on the surface of the fracture was mainly composed of sulfide, and the content was high; the fracture was brittle fracture. The cracking of the tee has the characteristics of hydrogen sulfide stress corrosion cracking.

Figure 9 Energy spectrum analysis of corrosion products on the fracture's surface

Figure 10 Energy spectrum analysis results of corrosion pits on the inner wall of the tee

The manufacturing process was not strictly implemented for the stainless steel tee in the manufacturing process, which led to the precipitation of σ phase in the metallographic structure, and a solution treatment was not performed after manufacturing, reducing the corrosion resistance of the material. Corrosion pits were generated under the long-term action of chloride ions in corrosive media. The appearance of corrosion pits became the source of induced cracks. Stress corrosion cracks easily generated in the wet hydrogen sulfide environment. After the overhaul, the hydrogen sulfide content increased sharply, approximately 10 times higher than that in the past. The corrosiveness of the medium increased sharply, which intensified the susceptibility of stress corrosion of hydrogen sulfide. At the same time, since the temperature of the medium was 30 to 40℃, it was also within the sensitive temperature range of hydrogen sulfide's stress corrosion. The appearance of corrosion pits was the source of induced cracks. The sharp increase of hydrogen sulfide content accelerated the hydrogen sulfide stress corrosion rate and cracking rate of cracks, which caused the stainless steel tee to crack in a short time.

6. Conclusion

(1) The chemical composition of the tee met the chemical composition of 0Cr18Ni9 required in the standard, and the chemical composition was qualified.

(2) The cracking of the stainless steel tee was stress corrosion cracking under the combined action of chloride ions and hydrogen sulfide in a wet environment.

(3) The main cause of cracking was that the mass concentration of hydrogen sulfide has increased from less than 1 g/L in the past to 7 to 10 g/L now.

The mass concentration of the harmful substance which was hydrogen sulfide has increased sharply, causing the corrosiveness of the medium to increase sharply. At the same time, the presence of chloride ions in the medium accelerated the hydrogen sulfide's stress corrosion rate. The manufacturing process of the stainless steel tee wasn't strictly implemented in the manufacturing process, which led to the precipitation of σ phase in the metallographic structure. Not undergoing a solution treatment after manufacturing reduced the corrosion resistance of the material, and corrosion pits were generated under the action of chloride ions in the corrosive medium for a long time and became the source of induced cracks. The joint action of the two caused the cracking of the stainless steel tee.

7. Recommendations

(1) Control and reduce the chloride ion content in the material.

(2) Inspect stainless steel pipe fittings in the same batch and perform regular inspections.

(3) Use gas detectors to strengthen on-site inspections to ensure safe operation.

(4) Control the quality of stainless steel pipe fittings. It is recommended to choose better materials when conditions permit.

Post URL: https://www.landeepipefitting.com/analysis-of-failure-causes-of-tees-in-inlet-pipelines-of-hydrocracking-pumps-part-two.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Failure Causes of Tees in Inlet Pipelines of Hydrocracking Pumps(Part One)

Next: The Cause Analysis of Perforated Elbows for Cracking Furnaces

Next: The Cause Analysis of Perforated Elbows for Cracking Furnaces