Classifications and Characteristics of Reducers

Posted: 12/22/2021 04:03:32 Hits: 90

A pressure pipeline, as one of the main special pressure bearing equipment for transporting various fluid media, has gradually gotten into our industrial production and people's lives, and can be seen everywhere in various industries. Restricted by the unique working conditions of the pressure pipeline and the special nature of its conveying medium, the safety of the pressure pipeline and the pipe fitting structure is particularly important. Once an accident occurs, it will cause serious consequences.

As a key component in the transportation of the pipeline, a reducer plays a vital role in the safe production and operation of pressure pipelines. However, there are still very few domestic researches on related issues such as stress analysis and safety assessment of reducers. Moreover, there are only relevant assessment methods applicable to straight sections of pressure pipelines in the standards currently used in China, and there are no relevant assessment methods applicable to reducers and other pipe fittings.

Classifications of reducers

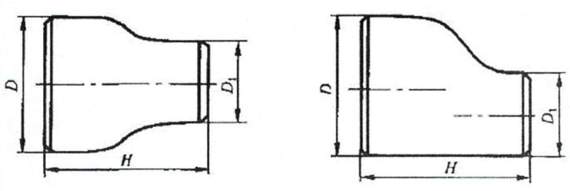

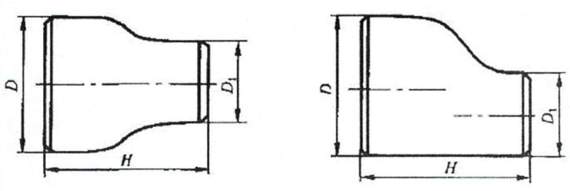

A reducer is one of the commonly used piping components, which is used to connect two pipes of different diameters. Commonly used reducers are concentric reducers and eccentric reducers, as shown in Figure 1.

As a key component in the transportation of the pipeline, a reducer plays a vital role in the safe production and operation of pressure pipelines. However, there are still very few domestic researches on related issues such as stress analysis and safety assessment of reducers. Moreover, there are only relevant assessment methods applicable to straight sections of pressure pipelines in the standards currently used in China, and there are no relevant assessment methods applicable to reducers and other pipe fittings.

Classifications of reducers

A reducer is one of the commonly used piping components, which is used to connect two pipes of different diameters. Commonly used reducers are concentric reducers and eccentric reducers, as shown in Figure 1.

(a) Concentric reducers (b) Eccentric reducers

Figure 1 Concentric reducers and eccentric reducers

There are various classifications, which are as follows:

(1) Classified by processing technologies: reducers can be divided into pushed reducers, plate welded reducers and forged reducers.

(2) According to the connecting method of reducers and pipelines, they can be divided into butt welded reducers, socket welded reducers and threaded reducers.

(3) Classifications according to structural shapes: reducer can be divided into eccentric reducers, concentric reducers and reducer elbows.

It can be seen that there are many types of reducers. It is advisable to conduct a comprehensive study of a specific type in theory, so as not to put it into any type of reducer that has been classified.

Some characteristics of reducers

Structural features

There are various classifications, which are as follows:

(1) Classified by processing technologies: reducers can be divided into pushed reducers, plate welded reducers and forged reducers.

(2) According to the connecting method of reducers and pipelines, they can be divided into butt welded reducers, socket welded reducers and threaded reducers.

(3) Classifications according to structural shapes: reducer can be divided into eccentric reducers, concentric reducers and reducer elbows.

It can be seen that there are many types of reducers. It is advisable to conduct a comprehensive study of a specific type in theory, so as not to put it into any type of reducer that has been classified.

Some characteristics of reducers

Structural features

(1) Usually, a reducer has structure of thin shells.

(2) Except for concentric reducers, the structure of a reducer is non-axisymmetric; strictly, it doesn't belong to a rotating shell.

(3) Even if both ends of the reducer are connected to a straight pipe of equal diameters and wall thicknesses, there are structural changes at the section where the diameter begins to change.

(4) The reducer often has the characteristics of uneven wall thicknesses and non-circular cross section due to the limitation of the manufacturing process.

(5) Deformation: great deformation is prone to occur under the action of bending moment load, and great plastic deformation only occurs partially. The torque is more likely to cause cross-section warping of eccentric reducers and reducer elbows.

In summary, a reducer has many features that a straight pipe doesn't, and there are differences and common features between reducers of different structures. On the one hand, these characteristics show that people's understanding of a reducer is not complete, which brings difficulties to the analysis of it, and on the other hand, clues can also be provided to its analysis. The unique characteristics of a reducer cannot be ignored because it is similar to other pipeline components, nor can its stress state be replaced by that of the straight pipe connected at its both ends because of these difficulties.

(5) Deformation: great deformation is prone to occur under the action of bending moment load, and great plastic deformation only occurs partially. The torque is more likely to cause cross-section warping of eccentric reducers and reducer elbows.

In summary, a reducer has many features that a straight pipe doesn't, and there are differences and common features between reducers of different structures. On the one hand, these characteristics show that people's understanding of a reducer is not complete, which brings difficulties to the analysis of it, and on the other hand, clues can also be provided to its analysis. The unique characteristics of a reducer cannot be ignored because it is similar to other pipeline components, nor can its stress state be replaced by that of the straight pipe connected at its both ends because of these difficulties.

Post URL: https://www.landeepipefitting.com/classifications-and-characteristics-of-reducers.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Analysis of the Causes of Cracks in the Welded Joints of Tees in a Power Plant (Part Two)

Next: Safety Assessment of Pressure Pipelines

Next: Safety Assessment of Pressure Pipelines