Cracking of Welding Seams of Eccentric Reducers in Ultra-high Pressure Steam Pipelines (Part Two)

Posted: 01/29/2024 07:12:01 Hits: 22

3. Historical failures and maintenance summary

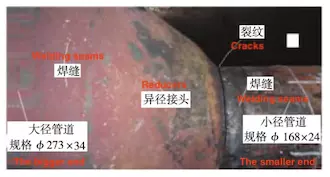

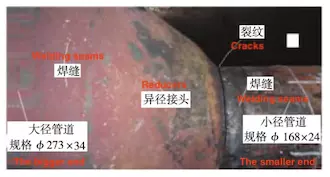

On June 25, 2006, cracking occurred at the same position as the reducer of the high-pressure steam main pipe of the No. 1 furnace. The cracking position was located on the fusion line of the small end’s welding seam of the reducer, and cracked from the upper part along the fusion line downwards, as shown in figure 4.

Figure 3 The structure of straight tubes

Figure 4 The appearance of the cracked reducer of the high-pressure steam main pipe of the No. 1 furnace

3.1 The situation of detection

At that time, the crack should be repaired, and it was impossible to take samples for analysis. It could only be preliminary through on-site partial inspection. The temperature was ultimately controlled at 150 to 200°C due to the high temperature. Metallographic testing could not be performed, and the hardness testing could only be used as a reference at this temperature. After hardness testing, the hardness value of the base material of the straight pipe and the heat-affected zone is 149 to 160 HB; the hardness value of the welding seam is 219 to 222 HB, base material and heat-affected zone of the reducer 175 to 191 HB; the hardness test is normal.

3.2 Analysis results

Preliminary analysis shows that the cause of the cracking is the stress concentration and temperature difference stress superposition of pipelines caused by the discontinuous shape of the eccentric reducer, resulting in cracking in the weak areas of the welding seam.

4. Comprehensive analysis and preventive measures for cracks in ultra-high pressure steam pipelines

4.1 The analysis of test results

Through visual inspection, hardness testing, composition and metallographic testing, it is shown that the current performance of the material is consistent with its service time. Compared with the test results in 2006, the overall hardness value has dropped significantly, and the spheroidization degree of the metallographic structure has reached a maximum level of 3.5, indicating that with the extension of use time, the comprehensive mechanical properties of the material have declined, especially the surface strength has dropped significantly. From the size of the crack and the crack expansion, it can be determined that the crack’s initiation point is at the upper part.

4.2 The analysis of stress

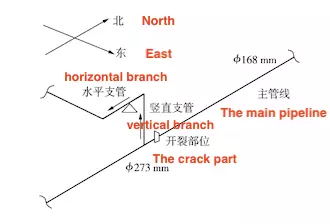

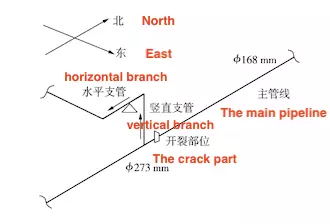

During the start-up of the cracked pipeline, when the temperature rises from normal temperature, there will be axial displacement due to the influence of thermal stress, as well as the tensile stress of the upward branch pipe passing through the tee and the axial stress of the horizontal branch pipe, as shown in Figure 5. Judging from the deformation of the external insulating iron sheet of the horizontal branch pipe at the support position on site, the horizontal branch pipe has a displacement of about 100 mm to the south. After the temperature rises, the horizontal branch pipe together with the vertical branch pipe gives an upward tensile stress to the main pipe at the cracked site, forming an upward tensile stress on the main pipe at the cracked site. The upper part of the eccentric reducer has the greatest geometric discontinuity and is also the location with the greatest stress concentration. Under the combined action of upward tensile stress, it is easy to exceed the material strength and cause cracking.

Figure 5 The schematic diagram of single pipes of SS pipelines

4.3 A comparative analysis of secondary cracking of SS pipes

The high-pressure steam pipeline cracked that occurred on June 25, 2006 had several features in common with this crack of high-pressure steam pipelines.

1) The locations where cracks occur are located in the heat-affected zone of the welding seam at the small end of the eccentric reducer.

2) Cracking occurs in the upper half of the reducer’s welding seam.

3) There is a vertical branch near the cracking point, and the flexible design of the pipeline is the same.

The two cracks can be determined to be that the pipeline cracked at a weak location due to the release of temperature difference stress in the piping system. Therefore, the properties of the two cracks can be classified as cracks of the same type and cause. The time when cracking occurred in 2006 was nearly 16 years ago, so the occurrence of cracking caused by material factors can be ruled out.

4.4 Frequent pressure increases and decreases

Frequent pressure increases and decreases in the SS pipeline system caused fatigue cracking of welding seams. The ultra-high pressure steam system was put into use in 1995. After checking, the maintenance time for comprehensive shutdown of the device and SS pipeline pressure increases and decreases was 19 times. When the SS pipeline heats up and cools, the welding seam at the cracked location is repeatedly stretched and compressed due to the expansion and contraction of the pipeline, resulting in fatigue damage to the welding seam and eventually causing fatigue cracking.

4.5 The analysis of temperature and pressure rise and fall of SS pipelines

The temperature rise of the cracking furnace is strictly operated in accordance with the operation manual. When the SS is connected to the grid, the pressure rise rate is 2.7MPa/h, which is less than the 3MPa/h required by the operation manual. The temperature rise process meets the operation requirements. At 20:30 on April 27, the SS pipe urgently depressurized due to the production needs of the rear system. Within 1.3 hours, the system pressure dropped from 10.17MPa to 4.96MPa. The depressurization speed was 4MPa/h, which exceeded the operating speed. The required 3MPa/h will cause a load impact on the pipeline.

4.6 Precautions

During the device maintenance period, conduct non-destructive testing, radiographic or conventional ultrasonic and phase control tests, magnetic particle, hardness testing of the eccentric reducer of the steam pipe, focusing on checking whether there are cracks. Before regular inspection of pipelines, review the plan to see if it is necessary to add non-destructive testing of pipeline supports and hangers, locations with significant displacement, locations where stress concentration may occur, reducers and tees. Randomly check the metallographic phase of the pipeline, and comprehensively determine the safe use of the pipeline based on the degree of spheroidization and hardness. In the start-up and shutdown process, especially for equipment that has been running for more than 20 years, the heating and cooling speed and the pressure increase and decrease speed should be controlled slowly to minimize the impact of temperature difference stress and load impact on the pipeline.

5. Conclusion

In summary, various testing data and analyses indicate that the SS pipeline has been in use for 27 years since it was started in 1995. After many times of temperature rises and falls, this part has been repeatedly subjected to tensile and compressive stress, and bainite spheroidization has occurred inside the material, causing the yield point, tensile strength and impact toughness of the material to decrease. The cracking of the ultra-high-pressure steam pipeline is located at the welding part between the eccentric reducer and the straight pipe. This part is the stress concentration part of the pipeline. Under the action of the temperature difference stress of the pipeline, cracking occurred in this weak part (the heat-affected zone of the eccentric reducer).

On June 25, 2006, cracking occurred at the same position as the reducer of the high-pressure steam main pipe of the No. 1 furnace. The cracking position was located on the fusion line of the small end’s welding seam of the reducer, and cracked from the upper part along the fusion line downwards, as shown in figure 4.

Figure 3 The structure of straight tubes

Figure 4 The appearance of the cracked reducer of the high-pressure steam main pipe of the No. 1 furnace

3.1 The situation of detection

At that time, the crack should be repaired, and it was impossible to take samples for analysis. It could only be preliminary through on-site partial inspection. The temperature was ultimately controlled at 150 to 200°C due to the high temperature. Metallographic testing could not be performed, and the hardness testing could only be used as a reference at this temperature. After hardness testing, the hardness value of the base material of the straight pipe and the heat-affected zone is 149 to 160 HB; the hardness value of the welding seam is 219 to 222 HB, base material and heat-affected zone of the reducer 175 to 191 HB; the hardness test is normal.

3.2 Analysis results

Preliminary analysis shows that the cause of the cracking is the stress concentration and temperature difference stress superposition of pipelines caused by the discontinuous shape of the eccentric reducer, resulting in cracking in the weak areas of the welding seam.

4. Comprehensive analysis and preventive measures for cracks in ultra-high pressure steam pipelines

4.1 The analysis of test results

Through visual inspection, hardness testing, composition and metallographic testing, it is shown that the current performance of the material is consistent with its service time. Compared with the test results in 2006, the overall hardness value has dropped significantly, and the spheroidization degree of the metallographic structure has reached a maximum level of 3.5, indicating that with the extension of use time, the comprehensive mechanical properties of the material have declined, especially the surface strength has dropped significantly. From the size of the crack and the crack expansion, it can be determined that the crack’s initiation point is at the upper part.

4.2 The analysis of stress

During the start-up of the cracked pipeline, when the temperature rises from normal temperature, there will be axial displacement due to the influence of thermal stress, as well as the tensile stress of the upward branch pipe passing through the tee and the axial stress of the horizontal branch pipe, as shown in Figure 5. Judging from the deformation of the external insulating iron sheet of the horizontal branch pipe at the support position on site, the horizontal branch pipe has a displacement of about 100 mm to the south. After the temperature rises, the horizontal branch pipe together with the vertical branch pipe gives an upward tensile stress to the main pipe at the cracked site, forming an upward tensile stress on the main pipe at the cracked site. The upper part of the eccentric reducer has the greatest geometric discontinuity and is also the location with the greatest stress concentration. Under the combined action of upward tensile stress, it is easy to exceed the material strength and cause cracking.

Figure 5 The schematic diagram of single pipes of SS pipelines

4.3 A comparative analysis of secondary cracking of SS pipes

The high-pressure steam pipeline cracked that occurred on June 25, 2006 had several features in common with this crack of high-pressure steam pipelines.

1) The locations where cracks occur are located in the heat-affected zone of the welding seam at the small end of the eccentric reducer.

2) Cracking occurs in the upper half of the reducer’s welding seam.

3) There is a vertical branch near the cracking point, and the flexible design of the pipeline is the same.

The two cracks can be determined to be that the pipeline cracked at a weak location due to the release of temperature difference stress in the piping system. Therefore, the properties of the two cracks can be classified as cracks of the same type and cause. The time when cracking occurred in 2006 was nearly 16 years ago, so the occurrence of cracking caused by material factors can be ruled out.

4.4 Frequent pressure increases and decreases

Frequent pressure increases and decreases in the SS pipeline system caused fatigue cracking of welding seams. The ultra-high pressure steam system was put into use in 1995. After checking, the maintenance time for comprehensive shutdown of the device and SS pipeline pressure increases and decreases was 19 times. When the SS pipeline heats up and cools, the welding seam at the cracked location is repeatedly stretched and compressed due to the expansion and contraction of the pipeline, resulting in fatigue damage to the welding seam and eventually causing fatigue cracking.

4.5 The analysis of temperature and pressure rise and fall of SS pipelines

The temperature rise of the cracking furnace is strictly operated in accordance with the operation manual. When the SS is connected to the grid, the pressure rise rate is 2.7MPa/h, which is less than the 3MPa/h required by the operation manual. The temperature rise process meets the operation requirements. At 20:30 on April 27, the SS pipe urgently depressurized due to the production needs of the rear system. Within 1.3 hours, the system pressure dropped from 10.17MPa to 4.96MPa. The depressurization speed was 4MPa/h, which exceeded the operating speed. The required 3MPa/h will cause a load impact on the pipeline.

4.6 Precautions

During the device maintenance period, conduct non-destructive testing, radiographic or conventional ultrasonic and phase control tests, magnetic particle, hardness testing of the eccentric reducer of the steam pipe, focusing on checking whether there are cracks. Before regular inspection of pipelines, review the plan to see if it is necessary to add non-destructive testing of pipeline supports and hangers, locations with significant displacement, locations where stress concentration may occur, reducers and tees. Randomly check the metallographic phase of the pipeline, and comprehensively determine the safe use of the pipeline based on the degree of spheroidization and hardness. In the start-up and shutdown process, especially for equipment that has been running for more than 20 years, the heating and cooling speed and the pressure increase and decrease speed should be controlled slowly to minimize the impact of temperature difference stress and load impact on the pipeline.

5. Conclusion

In summary, various testing data and analyses indicate that the SS pipeline has been in use for 27 years since it was started in 1995. After many times of temperature rises and falls, this part has been repeatedly subjected to tensile and compressive stress, and bainite spheroidization has occurred inside the material, causing the yield point, tensile strength and impact toughness of the material to decrease. The cracking of the ultra-high-pressure steam pipeline is located at the welding part between the eccentric reducer and the straight pipe. This part is the stress concentration part of the pipeline. Under the action of the temperature difference stress of the pipeline, cracking occurred in this weak part (the heat-affected zone of the eccentric reducer).

Post URL: https://www.landeepipefitting.com/cracking-of-welding-seams-of-eccentric-reducers-in-ultra-high-pressure-steam-pipelines-part-two.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Cracking of Welding Seams of Eccentric Reducers in Ultra-high Pressure Steam Pipelines (Part One)

Next: High-temperature Steam Pipe Reducers

Next: High-temperature Steam Pipe Reducers