Cracks of Reducers

Posted: 05/10/2023 11:34:46 Hits: 16

Abstract: Through the comprehensive analysis of reducers of the cracked residual oil hydrogenation cold high-pressure bottom sewage pipeline, the results show that under high hydrogen sulfide content and high pressure, even if the sulfur content of carbon steel reaches 0.003% (mass fraction), hydrogen-induced cracking can also be caused by brittle inclusions.

Introduction

The residual oil hydrogenation unit of a Petrochemical Refinery was put into operation in December 1999. The cold high-resolution bottom sewage pipeline was put into use at the same time. Its reducer is a carbon steel forging used to connect the cold high-resolution bottom and the angle regulating valve, and is made of ASTM A234/A234m-910W PB. The reducer was found to be cracked on March 7, 2001, and high-pressure water and H2S were ejected. The accident didn’t become more serious due to timely discovery and cutting off the upstream valve immediately. The device is operated for one year and three months.

2. Macro analysis

A straight crack with an axial length of 4.5 cm can be seen on the surface of the cracked reducer, and corrosion exists for the inner wall. After opening, the inner wall is covered with a dark black product, but after a period of time, it turns into a yellowish-brown product. The fracture is flat, which is a brittle fracture, and there are radial lines on the fracture; the radiation center is the source of the fracture. This source is 15mm away from the end of the reducer, which is the most concave part of the funnel-shaped reducer. However, there are small pits at the fracture source, which correspond to the corrosion pits on the inner wall of the reducer. The chemical composition of the cracked samples was analyzed as shown in Table 1. From the results of its chemical analysis, it can be seen that the reducer is carbon steel with high purity. Its S and P contents are very low, both of which are less than 0.005%, but the Mn content is higher than that of ordinary carbon steel.

Table 1 Analysis results of the chemical composition of the cracked reducers (%)

Table 1 Analysis results of chemical composition of the cracked reducers (%)

Introduction

The residual oil hydrogenation unit of a Petrochemical Refinery was put into operation in December 1999. The cold high-resolution bottom sewage pipeline was put into use at the same time. Its reducer is a carbon steel forging used to connect the cold high-resolution bottom and the angle regulating valve, and is made of ASTM A234/A234m-910W PB. The reducer was found to be cracked on March 7, 2001, and high-pressure water and H2S were ejected. The accident didn’t become more serious due to timely discovery and cutting off the upstream valve immediately. The device is operated for one year and three months.

2. Macro analysis

A straight crack with an axial length of 4.5 cm can be seen on the surface of the cracked reducer, and corrosion exists for the inner wall. After opening, the inner wall is covered with a dark black product, but after a period of time, it turns into a yellowish-brown product. The fracture is flat, which is a brittle fracture, and there are radial lines on the fracture; the radiation center is the source of the fracture. This source is 15mm away from the end of the reducer, which is the most concave part of the funnel-shaped reducer. However, there are small pits at the fracture source, which correspond to the corrosion pits on the inner wall of the reducer. The chemical composition of the cracked samples was analyzed as shown in Table 1. From the results of its chemical analysis, it can be seen that the reducer is carbon steel with high purity. Its S and P contents are very low, both of which are less than 0.005%, but the Mn content is higher than that of ordinary carbon steel.

Table 1 Analysis results of the chemical composition of the cracked reducers (%)

Table 1 Analysis results of chemical composition of the cracked reducers (%)

| C | Mn | Si | S | P | Cr |

| 0.12 | 0.88 | 0.25 | 0.003 | 0.004 | 0.056 |

The macroscopic hardness (HRB) of the cracked area of the reducer and the heat-affected zone near the welding seam was measured, and the results are as follows:

If it is in the hot forging state, the hardness of the carbon steel is generally 117 to 129HB, and the measured results are all lower than this value; the hardness of the heat-affected zone is even lower, only 82HB. It shows that the reducer is fully annealed at high temperatures after forging.

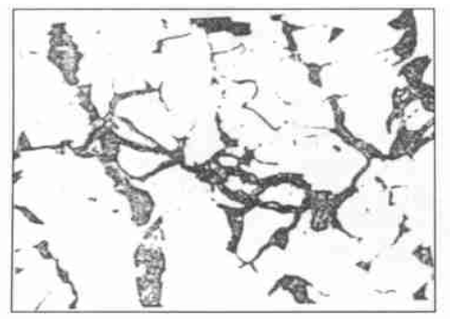

The non-etched samples at the cracks of the reducer are inspected under a metallographic microscope 100 times, and the levels of both brittle inclusions and plastic inclusions are lower than 0.5. Coarse inclusions or elongated MnS inclusions are rarely seen in cracks. The metallographic structure of the reducer is ferrite plus net pearlite (Figure 1), and the ferrite grains are fine and equiaxed. The grain size of ferrite is Grade 7.5. Observe the direction of the crack and its relationship with the structure under a magnification of 500 times. The cracks are both transgranular and intergranular, but they all pass through the pearlite grains. The cracks are relatively close, and there are not many corrosion products. There are still fine bifurcations around the main crack, ranging in size from 1 or 2 grains. It belongs to stress corrosion cracking.

Figure 1 The microstructure of cracked reducers under a magnification of 350 times

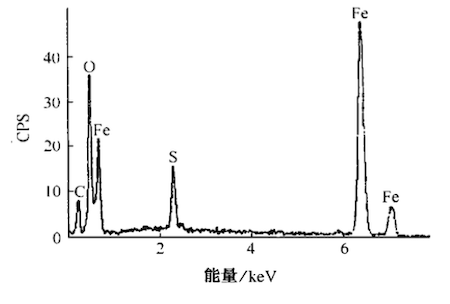

The surface of the fracture is covered with a layer of black products, which are Fe, S, O and C (Figure 2) through qualitative analysis by energy spectrum (Figure 2). The O content is very high, indicating that there are Fe3O4 products besides FeS. Further observation of the surface distribution of other elements shows that except for the partial gathering of S, the rest are evenly distributed. Therefore, the products are still mainly iron oxide and iron sulfide.

Figure 2 Qualitative analysis of energy spectrum

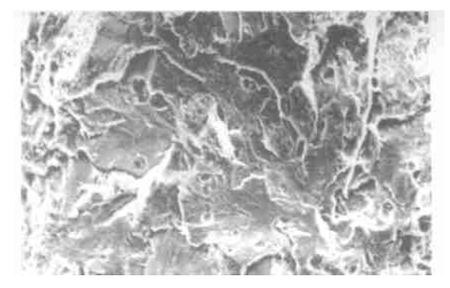

The morphology observed by scanning electron microscope after fracture cleaning is shown in Figure 3. It can be seen from the figure that the fracture is a compound fracture morphology, with intergranular and transgranular cleavage cracking, and dimple morphology and secondary cracks appear partially. The overall morphology is typical of hydrogen-induced cracking (HIC). What attracted special attention was the discovery of circular brittle inclusions at the source of the fracture (Figure 4), which indicated that the cracking of reducers was still related to the inclusions, even though the diameter of the inclusions was only about 30μm, and they were brittle inclusions. The crack initiation of H IC still starts from this.

Figure 3 Microscopic appearance of the fracture after cleaning at a magnification of 260 ×

Figure 4 Morphology of inclusions at the fracturing source

Post URL: https://www.landeepipefitting.com/cracks-of-reducers.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.