Factors Affecting Electrodeposition on the Inner Wall of Pipe Fittings

Posted: 11/28/2024 05:14:16 Hits: 9

Abstract: Many factors affect electrodeposition on the inner wall of pipe fittings. This paper mainly discusses the influence of the pretreatment process and current properties on electrodeposition in these applications.

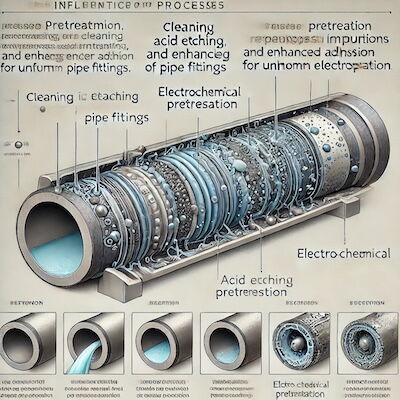

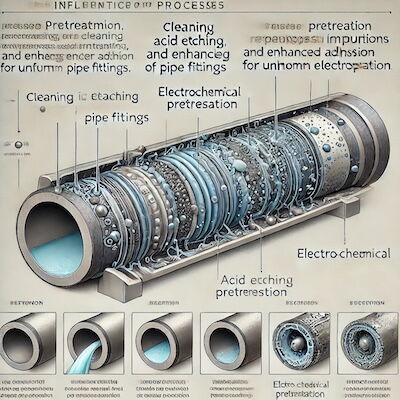

Influence of Pretreatment Process on Electrodeposition on the Inner Wall of Pipe Fittings

Pretreatment is an essential part of preparing electrodeposition coatings. The main purpose of pretreatment is to remove defects, oil stains, impurities, and oxide layers on the workpiece surface, thereby improving coating uniformity and its adhesion to the substrate. Statistics indicate that up to 40% of defective products in the electroplating industry result from poor pretreatment. Consequently, pretreatment in electroplating has received increasing attention. Feng Zhang and others systematically discussed the influence of the pretreatment process on coating adhesion strength in aluminum and aluminum alloy electrodeposition based on production practices. They proposed key points and relevant measures to enhance adhesion strength. Electroplating pretreatment is typically complex, requiring specific treatment processes for different substrate materials and surface conditions. Even for the same material, different pretreatment processes yield varying effects. Guikai Zhang compared the microstructure and adhesion strength of aluminum coatings on stainless steel surfaces after acid etching and electrochemical pretreatment, concluding that electrochemical pretreatment is the superior method, as shown in Table 1. It is important to note that electroplating pretreatment should not affect the geometric accuracy or basic performance of the workpiece.

Since inner wall electrodeposition technology for pipe fittings is more challenging, electroplating pretreatment becomes especially important, as it directly affects the uniformity of the inner wall coating on the workpiece. Zhang and others used an acid etching method to pretreat the cathode surface before electrodeposition on the inner wall of a Ni-based alloy tube, resulting in a Ni metal layer with good bonding strength and oxidation resistance. Xue and others electroplated Al on the inner wall of a meter-long 316L pipe. When the electrochemical pretreatment process was used, they found that the pretreatment current density significantly influenced the bonding strength of the subsequent electrodeposited coating. When the current density is no greater than 5 mA/cm², the Al coating is prone to detachment; at a current density of 10 mA/cm², however, the Al coating is firmly bonded. Consequently, the electroplating pretreatment process varies for pipes made of different materials. Commonly used pretreatment methods include acid/alkali etching, electrochemical treatment, and combinations of multiple methods. During electrochemical pretreatment, a well-designed inner anode is also necessary to improve the uniformity of the pipe’s inner wall.

Table 1 Effect of pretreatment process on electrodeposited Al coatings on stainless steel surface

Since inner wall electrodeposition technology for pipe fittings is more challenging, electroplating pretreatment becomes especially important, as it directly affects the uniformity of the inner wall coating on the workpiece. Zhang and others used an acid etching method to pretreat the cathode surface before electrodeposition on the inner wall of a Ni-based alloy tube, resulting in a Ni metal layer with good bonding strength and oxidation resistance. Xue and others electroplated Al on the inner wall of a meter-long 316L pipe. When the electrochemical pretreatment process was used, they found that the pretreatment current density significantly influenced the bonding strength of the subsequent electrodeposited coating. When the current density is no greater than 5 mA/cm², the Al coating is prone to detachment; at a current density of 10 mA/cm², however, the Al coating is firmly bonded. Consequently, the electroplating pretreatment process varies for pipes made of different materials. Commonly used pretreatment methods include acid/alkali etching, electrochemical treatment, and combinations of multiple methods. During electrochemical pretreatment, a well-designed inner anode is also necessary to improve the uniformity of the pipe’s inner wall.

Table 1 Effect of pretreatment process on electrodeposited Al coatings on stainless steel surface

| Process | Appearance | Thickness | Interface Characteristics | Adhesion |

| Acid etching | Complete coating, with pitting on the substrate | Uniform | Tiny holes, with layering in the coating | Weak |

| Electrochemistry | Complete coating, with no pitting on the substrate | Uniform | No obvious interface, exhibiting a wavy structure | Strong |

The Influence of Current Properties on the Electrodeposition of the Inner Wall of Pipe Fittings

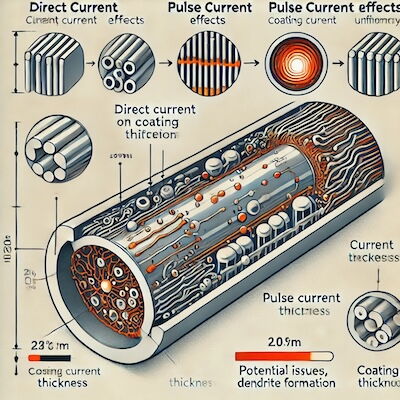

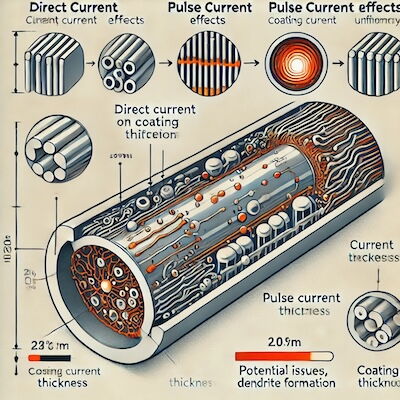

Once the configuration and arrangement of the anode and cathode are determined, the electrodeposition process is closely related to current properties, including current mode, current density, current efficiency, and current direction. Electrodeposition current modes are classified into two types: direct current and modulated current. Direct current is continuous and steady, with a constant direction over time, while modulated current is direct current altered by a pulse signal or other alternating signal, typically including unidirectional pulses, periodic commutation pulses, asymmetric alternating current, and AC/DC superposition. Among these, pulse plating is the most widely used modulated current electroplating method, offering many benefits, such as reducing coating porosity, enhancing bonding strength, improving deep plating and dispersion capabilities, reducing internal stress, and improving the coating's appearance as well as its mechanical and physical properties. Yang electroplated Al in an ionic liquid on the surface of brass and found that the coating obtained with pulse current was smoother, more uniform, and denser than that with direct current. Studies on micro-electroforming have also confirmed that periodic commutation pulse current can effectively improve the uniformity of electroformed deposits. Pulse current electroplating is essentially a periodic on-off DC electroplating process. When activated, its instantaneous high current density can reduce metal ions at a high overpotential, improving electroplating efficiency and refining the grains of the deposited layer. Additionally, the relaxation characteristics of pulse current increase cathode electrochemical polarization and reduce concentration polarization, enhancing the uniformity of the deposited layer. Currently, pulse current electroplating is successfully used for electrodepositing metal coatings, such as Ni, Al, and Gr, on the inner walls of pipe fittings.

According to Faraday's law, the metal deposition rate on the cathode surface primarily depends on the current density and is also related to current efficiency. Generally, in aqueous electroplating systems, current efficiency increases with increasing current density, while in anhydrous electroplating systems, such as ionic liquid electroplating, current efficiency decreases with increasing current density. There are also cases where current efficiency is independent of current density. In general simple salt electroplating processes (such as Ni plating and acidic Cu plating), the cathode's current efficiency does not significantly change with current density. When the current density is too low, most of the electrical energy is used to generate heat or reduce H+ in the plating solution to produce hydrogen, with only a small portion of the energy used to deposit the coating. This results in a thin coating, uneven thickness at both ends of the pipe, and even partial leakage plating. However, when the current density is too high, the electric lines may become too concentrated at the surface of the workpiece, sharp corners, and other areas. In aqueous electroplating systems, according to the theory of metal electrodeposition, within a certain range, as current density increases, the grain size of the deposited metal decreases, and excessive partial current density may lead to dendrite formation or crystal pulverization. However, in anhydrous systems, such as ionic liquid electroplating, the trend of grain size change with current density is reversed. This difference may be due to variations in the nucleation and growth mechanisms of coating grains in aqueous solutions and ionic liquids. Additionally, in alloy electrodeposition, the composition, content, and coating structure of the deposited layer are also related to current density. Mei'e Zhong and others found that the cobalt content in palladium-cobalt alloy coatings increased significantly with increasing current density. In the electrodeposition of amorphous alloys, increasing current density can transform the coating structure into an amorphous form (such as Fe-W alloy), and can also convert the amorphous structure into a crystalline state (such as Fe-Mo alloy). Clearly, in metal electrodeposition, the composition, structure, microstructure (such as grain size, morphology, orientation, interface characteristics, etc.), and formation rate of the deposited layer are closely related to current density, and this correlation may vary across different electroplating solution systems.

In the electrodeposition of the inner wall of the pipe, Yiming Chen and others found that the maximum plating current density is approximately linearly related to the inner anode diameter (Table 2), but excessive current density will cause the slot voltage to become unstable and may even exceed the power supply's regulation range. In addition, the electrodeposition process on the inner wall of the pipe is also influenced by the direction of the current. When the anode is powered from both ends to a unidirectional power supply from the upper end (opposite to the inlet of the plating solution), the uniformity of the Cr deposition layer thickness is significantly improved. Fengjiao He and others designed a current input method for electroplating tungsten alloy on the inner wall of a long oil pump barrel in a horizontal production line: the anode current is introduced from both ends, and the cathode current is introduced from the outer wall using multiple sets of brushes. Therefore, in the electrodeposition of the inner wall of the pipe, it is necessary to consider the influence of current properties (such as mode, density, efficiency, and direction) on the process and optimize the current parameters to achieve high-quality coatings.

Table 2 Relationships between the maximum current density and the diameter of inner anodes

According to Faraday's law, the metal deposition rate on the cathode surface primarily depends on the current density and is also related to current efficiency. Generally, in aqueous electroplating systems, current efficiency increases with increasing current density, while in anhydrous electroplating systems, such as ionic liquid electroplating, current efficiency decreases with increasing current density. There are also cases where current efficiency is independent of current density. In general simple salt electroplating processes (such as Ni plating and acidic Cu plating), the cathode's current efficiency does not significantly change with current density. When the current density is too low, most of the electrical energy is used to generate heat or reduce H+ in the plating solution to produce hydrogen, with only a small portion of the energy used to deposit the coating. This results in a thin coating, uneven thickness at both ends of the pipe, and even partial leakage plating. However, when the current density is too high, the electric lines may become too concentrated at the surface of the workpiece, sharp corners, and other areas. In aqueous electroplating systems, according to the theory of metal electrodeposition, within a certain range, as current density increases, the grain size of the deposited metal decreases, and excessive partial current density may lead to dendrite formation or crystal pulverization. However, in anhydrous systems, such as ionic liquid electroplating, the trend of grain size change with current density is reversed. This difference may be due to variations in the nucleation and growth mechanisms of coating grains in aqueous solutions and ionic liquids. Additionally, in alloy electrodeposition, the composition, content, and coating structure of the deposited layer are also related to current density. Mei'e Zhong and others found that the cobalt content in palladium-cobalt alloy coatings increased significantly with increasing current density. In the electrodeposition of amorphous alloys, increasing current density can transform the coating structure into an amorphous form (such as Fe-W alloy), and can also convert the amorphous structure into a crystalline state (such as Fe-Mo alloy). Clearly, in metal electrodeposition, the composition, structure, microstructure (such as grain size, morphology, orientation, interface characteristics, etc.), and formation rate of the deposited layer are closely related to current density, and this correlation may vary across different electroplating solution systems.

In the electrodeposition of the inner wall of the pipe, Yiming Chen and others found that the maximum plating current density is approximately linearly related to the inner anode diameter (Table 2), but excessive current density will cause the slot voltage to become unstable and may even exceed the power supply's regulation range. In addition, the electrodeposition process on the inner wall of the pipe is also influenced by the direction of the current. When the anode is powered from both ends to a unidirectional power supply from the upper end (opposite to the inlet of the plating solution), the uniformity of the Cr deposition layer thickness is significantly improved. Fengjiao He and others designed a current input method for electroplating tungsten alloy on the inner wall of a long oil pump barrel in a horizontal production line: the anode current is introduced from both ends, and the cathode current is introduced from the outer wall using multiple sets of brushes. Therefore, in the electrodeposition of the inner wall of the pipe, it is necessary to consider the influence of current properties (such as mode, density, efficiency, and direction) on the process and optimize the current parameters to achieve high-quality coatings.

Table 2 Relationships between the maximum current density and the diameter of inner anodes

| Inner Anode Diameter (mm) | Maximum Current Density (mA/cm²) |

| 2 | 1 |

| 3 | 2 |

| 4 | 2.5 |

| 6 | 3 |

Post URL: https://www.landeepipefitting.com/factors-affecting-electrodeposition-on-the-inner-wall-of-pipe-fittings.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Pictographic Anode for Pipe Fittings

Next: Factors Influencing Electrodeposition on the Inner Walls of Pipe Fittings

Next: Factors Influencing Electrodeposition on the Inner Walls of Pipe Fittings