Leakages of Pipe Caps of Hot-wall Tubes of Hydrogen Conversion Furnaces (Part Two)

Posted: 08/09/2021 10:31:31 Hits: 10

2.7 The analysis of the end of the crack

(1) The analysis of the macroscopic fracture: it could be seen that the surface of the fracture was uneven by intercepting the sample; dendritic crystal texture was visible, and the surface was oxidized and black.

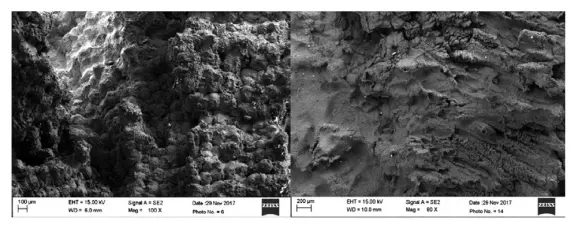

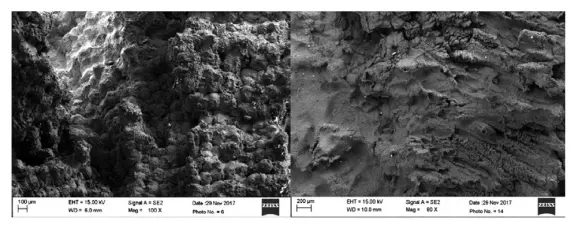

(2) The analysis of the microscopic morphology of the fracture: A scanning electron microscope (SEM) was used to observe and analyze the microscopic morphology of the fracture and impact fracture of the sample (as shown in Figure 2). The fracture showed characteristics of typical intergranular fracture, which had a shape of crystal sugar. The crystal grains were round and smooth, which was an intergranular fracture. There were oxide layers and spherical precipitates on the fracture surface; microcracks, cavities and a few dimples along the grain boundary could be seen on the fracture surface in the area where the crack tip of the material did not contact the medium. Plenty of oxides could be seen on the fracture surface near the outer surface and being in contact with the flue gas. The fracture surface of the impact sample was shaped like crystal sugar. The fracture mainly has the characteristics of brittle fracture, but also intergranular tough fracture.

2.8 EDS component analysis

EDS component analysis was performed on different parts of the sample, and the analysis results were shown in Table 5.

Table 5 The EDS component analysis

(1) The analysis of the macroscopic fracture: it could be seen that the surface of the fracture was uneven by intercepting the sample; dendritic crystal texture was visible, and the surface was oxidized and black.

(2) The analysis of the microscopic morphology of the fracture: A scanning electron microscope (SEM) was used to observe and analyze the microscopic morphology of the fracture and impact fracture of the sample (as shown in Figure 2). The fracture showed characteristics of typical intergranular fracture, which had a shape of crystal sugar. The crystal grains were round and smooth, which was an intergranular fracture. There were oxide layers and spherical precipitates on the fracture surface; microcracks, cavities and a few dimples along the grain boundary could be seen on the fracture surface in the area where the crack tip of the material did not contact the medium. Plenty of oxides could be seen on the fracture surface near the outer surface and being in contact with the flue gas. The fracture surface of the impact sample was shaped like crystal sugar. The fracture mainly has the characteristics of brittle fracture, but also intergranular tough fracture.

2.8 EDS component analysis

EDS component analysis was performed on different parts of the sample, and the analysis results were shown in Table 5.

Table 5 The EDS component analysis

| Fe | Ni | Cr | Nb | Mn | Si | Ti | F | |

| Base materials | 44.2 | 31.1 | 21.7 | 1.2 | 1.1 | 0.7 | ||

| Welding seams | 8.9 | 62 | 20.8 | 2.4 | 2.8 | 0.2 | 0.3 | 2.5 |

| Near the crack | 0.3 | 61.2 | 20.9 | 2.4 | 2.8 | 0.2 | 0.3 | 2.9 |

3. Comprehensive analysis

The chemical component C of the original tube slightly exceeded the standard based on the test results, and its organization was basically normal. ZG12Ni32Cr20Nb is a hypoeutectoid alloy, and the as-cast structure is austenite; there were fine carbides distributed inside the grains and on the grain boundaries. After long-term high-temperature operation, the microstructure would undergo a series of changes. It was found that a lot of carbides in the pipe material had precipitated at the grain boundary after metallographic inspection, resulting in more holes, hole chains and microcracks. The creep damage in some areas reached level 5, and there were obviously more holes and cracks in the high stress area than in other parts. The strength of the surface material had dropped significantly in the hardness test, and the toughness of the surface material in the impact test was very poor, indicating that the cap suffered serious creep damage. Comprehensive analysis, the main reason for the failure of the pipe cap was that the hard phase of carbides such as niobium carbide and chromium carbide in the material precipitated and continuously distributed at the grain boundary under the action of high temperature, which led to the weakening of the grain boundary, reducing the strength of the grain boundary, and greatly reducing the overall toughness of the material. Under the action of high temperatures and stress, creep damage happened to the material. Under the action of the internal pressure of the medium in the tube, crack sources were first generated at the weakest part of the grain boundary and at the interface between the dispersed particle carbide phase and the parent phase, and then holes were formed by shearing. The holes grew and connected to form intergranular fractures. The higher the proportion of the size of the carbide phase in the crystal interface was, the easier it was to form brittle fractures along the crystal. The two parts with cracks, that is, the fillet corner of the inner wall and fusion zone, were also the places where stress concentration was most likely to occur in the entire cap structure under the action of medium pressure and thermal stress.

4. Suggestions

Perform 100% ultrasonic inspection on all furnace pipes to know the depth of cracks. Sample part of the furnace tube. Make a metallographic analysis to check the area ratio of microscopic holes and cracks. Creep damage is irreversible. Once damage or cracking is found, the service life of the component has been exhausted, which should be replaced. In addition to controlling the temperature of the furnace tube and the temperature difference between inside and outside, it is almost impossible to prevent creep damage for sensitive materials operating under creep conditions. Avoid stress concentration in the design and manufacturing, which can prolong the creep life of the material. The creep deformation rate is closely related to the material, load and temperature. The damage rate (strain rate) is sensitive to both load and temperature. A 12°C increase in temperature or a 15% increase in stress will reduce the remaining service life of the metal by half or more. The temperature of the furnace tube and temperature difference between inside and outside should be controlled as much as possible.

Post URL: https://www.landeepipefitting.com/leakages-of-pipe-caps-of-hot-wall-tubes-of-hydrogen-conversion-furnaces-part-two.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Leakages of Pipe Caps of Hot-wall Tubes of Hydrogen Conversion Furnaces (Part One)

Next: Failure Causes of Tees in Inlet Pipelines of Hydrocracking Pumps(Part One)

Next: Failure Causes of Tees in Inlet Pipelines of Hydrocracking Pumps(Part One)