Processing Surfaces of Pipe Bends

Posted: 10/22/2022 12:46:30 Hits: 10

The demand for bends is increasing and more demands on the efficiency and stability of the media transported by the bends are put forward due to the current development of product design in the direction of miniaturization, light weights, precision, and intelligence. People's research on the quality control of the inner surface of the bend has increased, and some new methods different from the traditional processing methods continue to emerge.

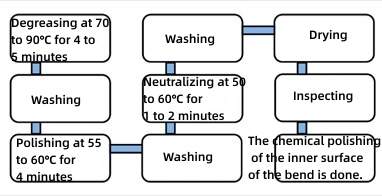

1. Chemical polishing processes

The chemical polishing of the inner surface of the bend is to select appropriate chemical reagents for the bend made from different materials to chemically etch and smooth the inner surface of the tube. The chemical polishing process flow is shown in Figure 1.

The process of chemical polishing the inner surface of the bend is simple, and the flowing chemical reagent can adapt to the changes in the shape and size of the pipe fittings and improve defects on the surface. However, uneven polishing will happen due to the unevenness of the original inner surface of the bend. In the process of chemical polishing, the reuse rate of chemical polishing liquid is low, which is easy to cause waste of resources. The chemical reaction also releases harmful gases, which will destroy the ecological environment.

2. Abrasive flow grinding and polishing processes

The working principle of abrasive flow grinding and polishing the inner surface of the bend is shown in Figure 2. Abrasive particles of different shapes are randomly mixed in the grinding and polishing liquid as a tool to form a solid-liquid two-phase abrasive particle flow and fill the inside of the bend. The tool clamps the bend end, and the piston rod reciprocates to exert pressure on the bend. The abrasive particles repeatedly rub against the inner wall of the bend to remove the debris. This method requires high pressure when grinding the inner surface of the bend. If the pressure is too great, the impact on the bending part will be more serious, and even cracks will occur. If the pressure is too low, there will be no obvious effect of grinding and polishing. Abrasive flow polishing has high requirements on fixtures, and it is difficult to unify fixtures for bends of different sizes.

Figure 2 The working principle of grinding and polishing the inner surface of the bend by abrasive flow

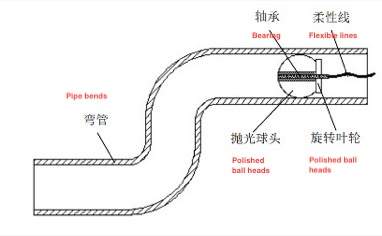

3. Rotating fluid jet polishing processes

The working principle of rotary fluid jet polishing of the inner surface of a bend is shown in Figure 3. Under the action of pressure, the polishing liquid containing abrasive particles is transported to the inside of the bend; the polishing liquid impacts the rotating impeller, and the impeller rotates and pushes the polishing ball head to move in the direction of the pipe diameter. At the same time, the polishing ball head rotates to squeeze the polishing liquid and the inner wall of the pipe fitting to achieve the purpose of grinding and polishing the inner surface of the bend. The rotating fluid jet polishing process grinds the bending part, and the polishing ball head is prone to jamming, which is not suitable for grinding the inner surface of the bend with small diameters.

Figure 3 The schematic diagram of rotating fluid jet polishing

4. Magnetic Abrasive Finishing

How Magnetic Abrasive Finishing (MAF) works on the inner surface of bends is shown in Figure 4.

Figure 4 The working principle of magnetic particle grinding on the inside surface of the bend

The inside of the bend is filled with magnetic abrasive particles, and the outer magnet yoke of the bend is surrounded by magnets. The bend is fixed and the magnet yoke drives the magnet to rotate around the bend according to the direction of rotation. The internal magnetic abrasive particles rotate with the external magnet, and continuously rub the inner wall of the bend to remove the debris. The magnet yoke rotates and reciprocates along the axis of the bend and complete the grinding of the inner surface of the bend. Magnetic particle grinding can effectively solve the problem of uneven quality of the inner surface of the bend and improve the service life of the bend.

Post URL: https://www.landeepipefitting.com/processing-surfaces-of-pipe-bends.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.