Research on Cold & Hot Forming of S31254 180° Elbows

Posted: 02/23/2022 08:14:42 Hits: 6

Abstract: The S31254 180° R=1D sharp turning elbow used in the high-temperature pyrolysis furnace of a company in the United States is currently manufactured by the casting process, and the steel pipe's manufacturing process is now used as the research object. The research content and key of the cold and hot manufacturing process of the sharp turning elbow is discussed, and the best process of manufacturing S31254 180° R=1D sharp turning elbows made of steel pipe is mastered, which provides a reference for the manufacture of similar products. The products manufactured according to this process are successfully used in a company's pyrolysis furnace, and their service lives are greatly improved than those of casting elbows.

The 180° S31254 sharp turning elbow used in the high-temperature oil pyrolysis furnace is currently manufactured by the casting process. The elbow manufactured by this process has disadvantages of a low structure density, intergranular corrosion easily caused by the high-temperature medium, poor wear resistance and short service life. A company in the United States entrusted our company to develop and manufacture 180° R=1D sharp turning elbows made of S31254 steel pipes to replace the elbows formed by casting. Two molding processes such as hot push molding and cold extrusion molding were adopted to trial-produce 180° R=1D sharp turning elbows, and researched 180° R=1D sharp turning elbows manufactured by different processes; finally, 180° R=1.0D sharp turning elbow bend made by cold extrusion molding was adopted. The sample was tested by a company from the United States, and its performance met the requirements.

The 180° sharp turning elbow has good corrosion resistance and high-temperature resistance, which can meet the quality requirements of the high-temperature oil pyrolysis furnace, and its service life is greatly improved. The S31254 180° sharp turning elbow developed was successfully used in the pyrolysis furnace of a project of a company in the United States in July 2016. The company conducts thickness measurement and metallographic inspection on this batch of pipe fittings every year, and their actual service lives are better than those made by the casting process.

Tests were conducted on pyrolysis furnaces with the more commonly used specifications, that is, 180° S31254 R=1D D60.3x5.54 sharp turning elbow manufactured by hot forming and cold forming methods.

1. Re-inspection of the material

The design and manufacture standard of 180° sharp turning elbow is ASME B16.9. The material of the seamless steel pipe we chose was ASTM A312 S31254, and the specifications were D60.3 x 6.0 (cold forming) and 48.3 x 6.0 (hot forming). After the materials entered the factory, the chemical composition and mechanical properties of the two materials were re-examined. The chemical composition, mechanical properties and re-examination results in the material certificate all met the requirements of relevant standards.

2. Forming research content and key technologies adopted

2.1 For the cold extrusion molding process, pre-forming and secondary molding were adopted to achieve the final molding of 180° sharp turning elbows. The analysis model and forming limit of the sharp turning elbow were also researched, and the effects of the cold extrusion forming axial feed rate, the main dimensional parameters of the elbow, the material's forming properties, and the lubrication conditions on the process parameters and forming results such as wall thickness, stress, and strain were studied. A prediction method and process for defects such as great wall thickness reduction and intergranular cracks in the forming process were proposed. The cold extrusion secondary forming process was also studied. Reasonably determined the matching relationship between the advancing amount and the advancing speed. In the extrusion process, intermediate heat treatment was used, and the cold extrusion process again reduced the occurrence of wall thickness reduction and intergranular cracks in the material forming process. Solution heat treatment was adopted after secondary molding to refine grain, eliminate stress and obtain uniform austenite structure.

2.2 The relationship among the determination of heating and heat preservation methods, the appropriate expansion ratio, the heat preservation temperature and the heat preservation device, the pushing speed and the wall thickness reduction amount was studied. After hot forming, the same solution heat treatment process was used as after cold forming.

2.3 We used secondary molding for cold forming, 1.5D preforming for bending, and solution heat treatment to restore the material properties after molding. The secondary molding used a special mold with the same bending radius as the required sharp turning elbow. After secondary molding, solid solution heat treatment was used. The pre-forming adopted a large bending radius mold, and the secondary molding adopted a special mold with the same bending radius as the required sharp turning elbow, which greatly reduced the thinning of the wall thickness and improved the ovality.

2.4 The use of intermediate heat treatment reduced the occurrence of intergranular cracks after deformation, eliminated stress concentration, and ensured the quality of secondary molding.

2.5 Multiple sets of external shaping blocks were used to ensure that the elbow was evenly stressed and prevented the elbow from being damaged during shaping.

3. A comparison of the size and performance of elbows made by cold and hot forming processes

3.1 The shapes and sizes of the 180° sharp turning elbow after forming were shown in Figures 1 to 4, Table 1 and Table 2.

Figure 1 Cold formed products

Figure 2 Thermoformed products

Table 1 Measurement results of outer diameters and wall thicknesses of elbows manufactured by cold forming processes

The 180° S31254 sharp turning elbow used in the high-temperature oil pyrolysis furnace is currently manufactured by the casting process. The elbow manufactured by this process has disadvantages of a low structure density, intergranular corrosion easily caused by the high-temperature medium, poor wear resistance and short service life. A company in the United States entrusted our company to develop and manufacture 180° R=1D sharp turning elbows made of S31254 steel pipes to replace the elbows formed by casting. Two molding processes such as hot push molding and cold extrusion molding were adopted to trial-produce 180° R=1D sharp turning elbows, and researched 180° R=1D sharp turning elbows manufactured by different processes; finally, 180° R=1.0D sharp turning elbow bend made by cold extrusion molding was adopted. The sample was tested by a company from the United States, and its performance met the requirements.

The 180° sharp turning elbow has good corrosion resistance and high-temperature resistance, which can meet the quality requirements of the high-temperature oil pyrolysis furnace, and its service life is greatly improved. The S31254 180° sharp turning elbow developed was successfully used in the pyrolysis furnace of a project of a company in the United States in July 2016. The company conducts thickness measurement and metallographic inspection on this batch of pipe fittings every year, and their actual service lives are better than those made by the casting process.

Tests were conducted on pyrolysis furnaces with the more commonly used specifications, that is, 180° S31254 R=1D D60.3x5.54 sharp turning elbow manufactured by hot forming and cold forming methods.

1. Re-inspection of the material

The design and manufacture standard of 180° sharp turning elbow is ASME B16.9. The material of the seamless steel pipe we chose was ASTM A312 S31254, and the specifications were D60.3 x 6.0 (cold forming) and 48.3 x 6.0 (hot forming). After the materials entered the factory, the chemical composition and mechanical properties of the two materials were re-examined. The chemical composition, mechanical properties and re-examination results in the material certificate all met the requirements of relevant standards.

2. Forming research content and key technologies adopted

2.1 For the cold extrusion molding process, pre-forming and secondary molding were adopted to achieve the final molding of 180° sharp turning elbows. The analysis model and forming limit of the sharp turning elbow were also researched, and the effects of the cold extrusion forming axial feed rate, the main dimensional parameters of the elbow, the material's forming properties, and the lubrication conditions on the process parameters and forming results such as wall thickness, stress, and strain were studied. A prediction method and process for defects such as great wall thickness reduction and intergranular cracks in the forming process were proposed. The cold extrusion secondary forming process was also studied. Reasonably determined the matching relationship between the advancing amount and the advancing speed. In the extrusion process, intermediate heat treatment was used, and the cold extrusion process again reduced the occurrence of wall thickness reduction and intergranular cracks in the material forming process. Solution heat treatment was adopted after secondary molding to refine grain, eliminate stress and obtain uniform austenite structure.

2.2 The relationship among the determination of heating and heat preservation methods, the appropriate expansion ratio, the heat preservation temperature and the heat preservation device, the pushing speed and the wall thickness reduction amount was studied. After hot forming, the same solution heat treatment process was used as after cold forming.

2.3 We used secondary molding for cold forming, 1.5D preforming for bending, and solution heat treatment to restore the material properties after molding. The secondary molding used a special mold with the same bending radius as the required sharp turning elbow. After secondary molding, solid solution heat treatment was used. The pre-forming adopted a large bending radius mold, and the secondary molding adopted a special mold with the same bending radius as the required sharp turning elbow, which greatly reduced the thinning of the wall thickness and improved the ovality.

2.4 The use of intermediate heat treatment reduced the occurrence of intergranular cracks after deformation, eliminated stress concentration, and ensured the quality of secondary molding.

2.5 Multiple sets of external shaping blocks were used to ensure that the elbow was evenly stressed and prevented the elbow from being damaged during shaping.

3. A comparison of the size and performance of elbows made by cold and hot forming processes

3.1 The shapes and sizes of the 180° sharp turning elbow after forming were shown in Figures 1 to 4, Table 1 and Table 2.

Figure 1 Cold formed products

Figure 2 Thermoformed products

Table 1 Measurement results of outer diameters and wall thicknesses of elbows manufactured by cold forming processes

| Items | Outer diameters of ends | Wall thicknesses | ||

| A | B | A | B | |

| 1 | 60.17 | 59.69 | 5.73 | 5.93 |

| 2 | 60.21 | 60.11 | 5.39 | 5.29 |

| 3 | 60.11 | 59.73 | 5.52 | 5.50 |

| 4 | 59.97 | 60.01 | 5.79 | 5.73 |

Table 2 The measurement results of the outer diameter and wall thickness of the elbow manufactured by the thermoforming process

| Items | Outer diameters of ends | Wall thicknesses | ||

| A | B | A | B | |

| 1 | 60.68 | 60.42 | 5.85 | 6.01 |

| 2 | 60.87 | 60.49 | 5.50 | 5.62 |

| 3 | 60.61 | 60.80 | 5.13 | 5.29 |

| 4 | 60.82 | 60.92 | 5.88 | 5.93 |

Figure 3 The cross-section of the cold-formed sharp turning elbow

Figure 4 The cross-section of the hot-formed sharp turning elbow

The outer diameter and wall thickness of the 180° the sharp turning elbow manufactured by hot forming and cold forming processes meet the requirements of ASME B16.9 standards.

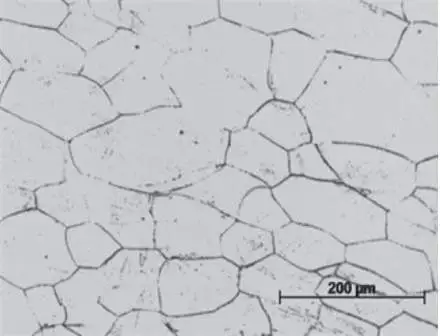

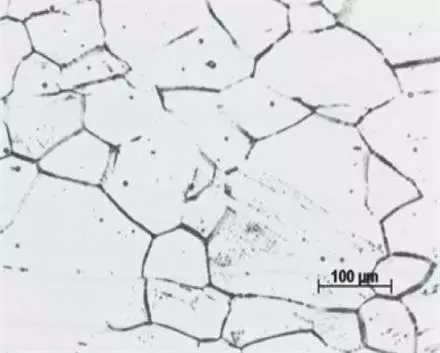

3.2 Microscopic metallography of the 180° sharp turning elbow after cold and hot forming

The metallographic phase of the elbow manufactured by the hot forming process was that austenite was roughly equiaxed, and there was a continuous carbide network at the grain boundary as shown in Figure 5. The metallographic phase of the elbow manufactured by the cold forming process was that the dendritic microstructure of austenite with a small amount of intergranular carbide precipitation is shown in Figure 6.

Figure 5 Metallographic phase of hot formed sharp turning elbow

Figure 6 Metallography of the cold formed sharp turning elbow

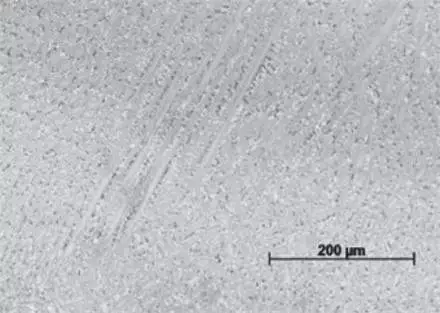

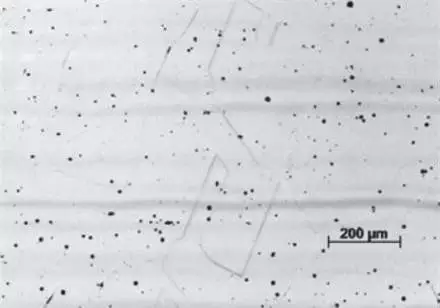

3.3 Microstructure after intergranular corrosion of 180° sharp turning elbows after cold and hot forming (ASTM A262 methods)

The microstructure of the elbow manufactured by the thermoforming process showed a groove structure after intergranular corrosion, as shown in Figure 7. The microstructure of the elbow manufactured by the cold forming process showed a stepped structure after intergranular corrosion, as shown in Figure 8.

Figure 7 Intergranular corrosion tests of hot-formed sharp turning elbows

A stepped structure is defined as only steps between particles, and a grooved structure is defined as one or more particles being surrounded by grooves.

Figure 8 Intergranular corrosion tests of cold formed sharp turning elbows

4. Conclusion

4.1 Compare with the 180° sharp turning elbows manufactured by cold forming and hot forming processes, hot forming will cause sensitization of S31254 within the sensitization range. The microstructure has obvious carbide precipitation (sensitization) at the grain boundaries. These carbides are chromium rich (Cr23C6), and their formation leads to chromium depletion zones close to the grain boundaries, which partially reduces corrosion resistance, resulting in greater susceptibility to intergranular corrosion. It is reflected in the ASTM A262E test; the microstructure has a grooved structure, that is, the area around the grain boundary has been attacked by an effective chemical.

4.2 The microstructure of the cold-formed 180° sharp turning elbow has austenite equiaxed grain structure without obvious grain boundary precipitation, and the microstructure shows a stepped structure. The use of suitable cold forming and solution heat treatment processes can better ensure the product quality of similar products.

Post URL: https://www.landeepipefitting.com/research-on-cold-hot-forming-of-s31254-180-elbows.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Leakages at the Connecting Part Between Flanges & Reducers in Quench Boilers

Next: The Failure Analysis of the Stainless Steel TP304 Tee (Part One)

Next: The Failure Analysis of the Stainless Steel TP304 Tee (Part One)