Research on Heating Temperatures and Sizes of Hot Forming of Pipe Caps (Part Two)

Posted: 06/07/2021 07:10:47 Hits: 13

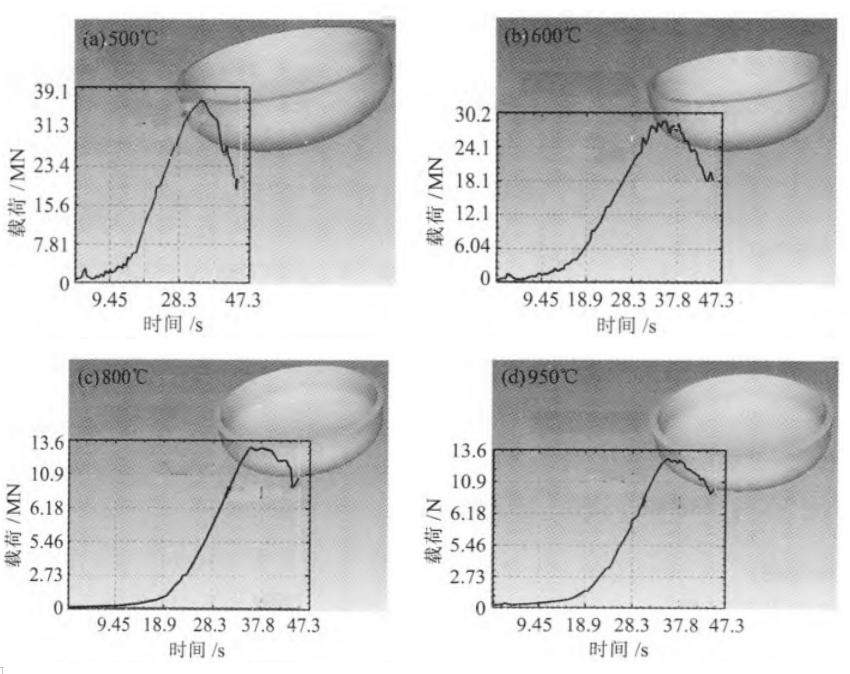

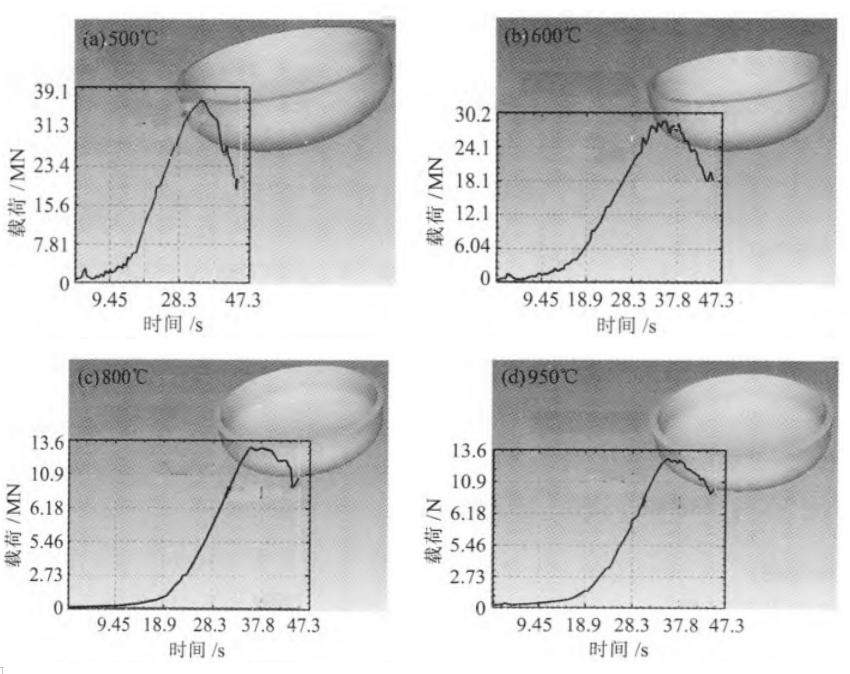

In order to observe the influence of the heating temperature of the material on the hot forming process, the heating temperature of the material of 500, 600, 800, and 950℃ are adopted to study the influence of the heating temperature on the forming force and product shape. The experimental simulation results are shown in Figure 3.

By studying the forming process of the material with different heating temperatures, the heating temperature does not affect the forming of the material. Under the same other conditions, different heating temperatures have achieved the ideal shape for the workpiece. Too low heating temperature will increase the deformation resistance of the metal, thus increasing the forming force. The forming force at a heating temperature of 500°C is nearly three times higher than that at a heating temperature of 950°C. Excessive forming force damages the mold greatly, and the economic value of the press with too great tonnage is also high. According to the actual experience, when the heating temperature exceeds 1000℃, there are also high requirements on the heating equipment, and it is easy to cause oxidation of the mold's surface. In conclusion, when the forming load can be met, the heating temperature of the metal should be 950°C in order to achieve the most economical effect.

3. Determination of the size of the metal

3.1 The theoretically calculated size of the metal

For the calculation method of the area of the cap's forming, according to JB4767-2002, the calculation formula of the surface area of the elliptical cap (EHA) is S=πr[r+h1xC+2h], r=D/2, h1=H-h, C=ln , for standard caps, C=0.760346. According to the size of the pipe cap D=1219 mm, H=381 mm, h=81 mm, t=34 mm, obtaining s=1.92m2.

, for standard caps, C=0.760346. According to the size of the pipe cap D=1219 mm, H=381 mm, h=81 mm, t=34 mm, obtaining s=1.92m2.

Taking into account the machining allowance, the area of the metal used is increased by 5%, that is, 1.92x1.05=2m2. The calculation formula for the radius of the metal is: S=πR2, and R=0.798m is obtained. The radius of the metal is 800 mm, that is, the metal of φ1600mmx34mm is selected.

3.2 Determination of the final size of the metal

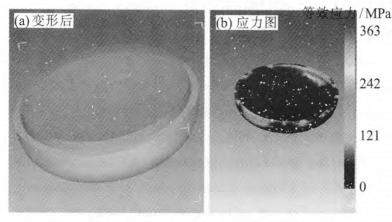

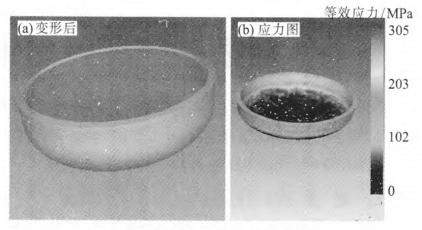

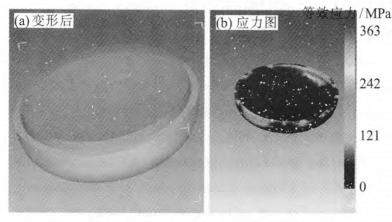

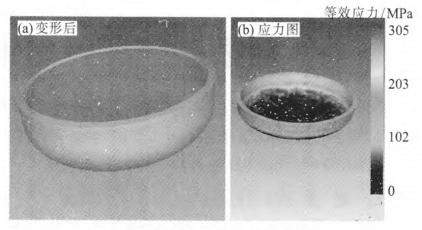

Through preliminary analysis, 1500 and 1600 mm are selected as the diameter of the pipe cap, and the thickness of the pipe cap is 34 mm. Simulate the forming process of the selected metal respectively, and the simulation results are shown in Figures 4 and 5.

Figure 4 Forming simulation of a cap with a diameter of 1500 mm

Figure 5 Forming simulation of a cap with a diameter 1600 mm

The above simulation results show that the size of the pipe cap is different, and the forming result is also different. From the forming simulation of the pipe cap with a diameter of 1500 mm, it can be seen that the shoulder of the cap does not have enough machining allowance after forming. From the forming simulation of the pipe cap with a diameter of 1600 mm, it can be found that the shoulder of the cap has sufficient machining allowance after forming. Therefore, the formed part with a diameter of 1600 mm is better than the one with a diameter of 1500 mm. Finally, the metal with a diameter of 1600 mm and a wall thickness of 34 mm is determined as the forming metal for a cap of φ1219 mm x 34 mm.

4. Conclusion

Through DEFORM-3D software, the hot pressing of the pipe cap of φ1219 mm x 341 mm is simulated, and the optimal heating temperature of the metal is determined to be 950℃. The size of the diameter is 1600 mm, and the wall thickness is 34 mm.

By studying the forming process of the material with different heating temperatures, the heating temperature does not affect the forming of the material. Under the same other conditions, different heating temperatures have achieved the ideal shape for the workpiece. Too low heating temperature will increase the deformation resistance of the metal, thus increasing the forming force. The forming force at a heating temperature of 500°C is nearly three times higher than that at a heating temperature of 950°C. Excessive forming force damages the mold greatly, and the economic value of the press with too great tonnage is also high. According to the actual experience, when the heating temperature exceeds 1000℃, there are also high requirements on the heating equipment, and it is easy to cause oxidation of the mold's surface. In conclusion, when the forming load can be met, the heating temperature of the metal should be 950°C in order to achieve the most economical effect.

3. Determination of the size of the metal

3.1 The theoretically calculated size of the metal

For the calculation method of the area of the cap's forming, according to JB4767-2002, the calculation formula of the surface area of the elliptical cap (EHA) is S=πr[r+h1xC+2h], r=D/2, h1=H-h, C=ln

, for standard caps, C=0.760346. According to the size of the pipe cap D=1219 mm, H=381 mm, h=81 mm, t=34 mm, obtaining s=1.92m2.

, for standard caps, C=0.760346. According to the size of the pipe cap D=1219 mm, H=381 mm, h=81 mm, t=34 mm, obtaining s=1.92m2.Taking into account the machining allowance, the area of the metal used is increased by 5%, that is, 1.92x1.05=2m2. The calculation formula for the radius of the metal is: S=πR2, and R=0.798m is obtained. The radius of the metal is 800 mm, that is, the metal of φ1600mmx34mm is selected.

3.2 Determination of the final size of the metal

Through preliminary analysis, 1500 and 1600 mm are selected as the diameter of the pipe cap, and the thickness of the pipe cap is 34 mm. Simulate the forming process of the selected metal respectively, and the simulation results are shown in Figures 4 and 5.

Figure 4 Forming simulation of a cap with a diameter of 1500 mm

Figure 5 Forming simulation of a cap with a diameter 1600 mm

The above simulation results show that the size of the pipe cap is different, and the forming result is also different. From the forming simulation of the pipe cap with a diameter of 1500 mm, it can be seen that the shoulder of the cap does not have enough machining allowance after forming. From the forming simulation of the pipe cap with a diameter of 1600 mm, it can be found that the shoulder of the cap has sufficient machining allowance after forming. Therefore, the formed part with a diameter of 1600 mm is better than the one with a diameter of 1500 mm. Finally, the metal with a diameter of 1600 mm and a wall thickness of 34 mm is determined as the forming metal for a cap of φ1219 mm x 34 mm.

4. Conclusion

Through DEFORM-3D software, the hot pressing of the pipe cap of φ1219 mm x 341 mm is simulated, and the optimal heating temperature of the metal is determined to be 950℃. The size of the diameter is 1600 mm, and the wall thickness is 34 mm.

Post URL: https://www.landeepipefitting.com/research-on-heating-temperatures-and-sizes-of-hot-forming-of-pipe-caps-part-two.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Research on Heating Temperatures and Sizes of Hot Forming of Pipe Caps (Part One)

Next: Reducing Cracks through the Manufacture and Post Treatment of Bends

Next: Reducing Cracks through the Manufacture and Post Treatment of Bends