-

The Analysis of Stress of Pipe Fittings

Posted: 11/15/2023 02:12:54 Hits: 1071.1 Elbows Elbows are mainly used to change the direction of pipes. There are two manufacturing and forming processes: one is the medium-frequency induction heating pushing process of steel pipe and the other is the press forming process of the steel pipe. There are differences between the two processes... -

Stainless Steel Tees

Posted: 10/25/2023 02:42:01 Hits: 8In the construction and engineering field, stainless steel tees have emerged as an indispensable component. These tees, made from a combination of iron, chromium, and other alloying elements, possess remarkable qualities that make them highly sought after in various industries. Firstly, stainless steel... -

Pipe Tees

Posted: 09/26/2023 03:52:54 Hits: 18Pipe tees are a fundamental component in pipe systems, serving as connectors for pipes of different diameters. These pipe fittings have a T-shaped design, with one inlet and two outlets at 90-degree angles. Pipe tees play a crucial role in directing the flow of fluids and ensuring efficient distribution... -

Reasons & Countermeasures for Steam Superheating Furnace Gas Collection Pipe Caps

Posted: 07/31/2023 07:56:12 Hits: 84. Scanning electron microscope observation and energy spectrum analysis The black powder remaining in the gas collecting pipe after shutdown was analyzed by scanning electron microscope energy spectrometers, and the results are shown in Figure 7. It shows that the main component of the powder is Fe... -

Inspecting Steam Superheating Furnace Gas Collection Pipe Caps

Posted: 07/10/2023 07:38:16 Hits: 5Abstract: The material taken from the failure part of the gas collection pipe outlet pipe cap in the radiation chamber of the steam superheating furnace was inspected for the macroscopic morphology of the corrosion part, chemical composition, inclusions, metallographic structure, oxides, scanning electron... -

Carbon Steel Pipe Fittings

Posted: 11/29/2022 11:00:36 Hits: 13Carbon steel pipe fittings with higher carbon content have better hardness and strength. They are used to connect two pipes with the same nominal diameter to make the pipe turn 90 degrees. Classifications of carbon steel pipe fittings Carbon steel can be divided into carbon structural steel,... -

The Forming of the Reducing Tee

Posted: 08/22/2022 03:30:27 Hits: 85Nowadays, with the rapid development of aviation enterprises, there are many applications of tee fittings to the system of aircraft. In traditional applications, the butt welding process or fillet welding process is used for forming the tee, as shown in Figure 1. Figure (a) is a butt welding that welds... -

The Overview of Development of Hydroforming

Posted: 07/14/2022 09:48:11 Hits: 13Hydroforming is a plastic forming process in which a certain force-transmitting medium fills the cavity of the tube blank and forms the tube from the inside out. Hydroforming is currently used as a precision forming technology for manufacturing some thin-walled tube parts with complex shapes, and it... -

The Development of Tees

Posted: 06/28/2022 10:20:38 Hits: 11A tee is an important part of the pressurization and conveying system of aircraft such as launch vehicles. It has functions of gathering and diversion of the multi pipes in the overall system. However, in the actual flight process, it is subject to certain pressure and structural stress. The quality... -

Advantages of Hydroforming Pipe Fittings

Posted: 06/15/2022 11:40:06 Hits: 11With the improvement of science, technology and productivity, the development and progress of the manufacturing industry to the intelligent manufacturing industry, various industries are undergoing rapid changes, showing the power of China to the world and making intelligent manufacturing go global,... -

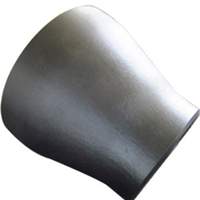

The Connection between Reducers of Heat Exchangers & Dissimilar Steel Pipes

Posted: 05/23/2022 08:46:28 Hits: 3Formulating the construction plan 1. Principles of welding carbon steel 20 and stainless steel 304 dissimilar steel According to the analysis of the weldability of austenitic stainless steel 304 and ferritic carbon steel 20 dissimilar steel, hot cracks easily happen when the two are welded, and the... -

The Connection Scheme between Reducers of Heat Exchangers and Pipes

Posted: 05/09/2022 07:45:34 Hits: 21Abstract: When a chemical plant is overhauled, two sets of overlapping fixed tube sheet heat exchangers are replaced. The carbon steel flanges at the inlet and outlet of the tube box are of different materials and specifications than the external stainless steel pipelines. In order to ensure that the...