-

Failure Analysis of the Cracking of Stainless Steel Tees in Industrial Pipelines (Part Two)

Posted: 05/10/2021 10:57:21 Hits: 402.6 The scanning electron microscope observation and energy spectrum analysis Sample at A according to the position shown in Figure 3 for the scanning electron microscope and energy spectrum analysis. Scanning electron microscopy results are shown in Figures 4 and 5. The crack fractures mostly... -

Failure Analysis of the Cracking of Stainless Steel Tees in Industrial Pipelines (Part One)

Posted: 04/27/2021 09:22:08 Hits: 20Abstract: An austenitic stainless steel tee in an industrial pipeline of a coal chemical plant cracked and failed in the use process. Inspection and sampling tests are performed for the tee in this article, including macroscopic inspection, hardness measurement, metallographic analysis... -

Scouring and Wear of Elbows

Posted: 04/06/2021 04:14:10 Hits: 13Pipelines, roads, railways, air and water transportation are the five major transportation. Among them, pipelines have the advantages of large transportation volume, small engineering volume, short transportation distances and low losses, which play an irreplaceable role in petroleum,... -

Quick Verification for Solution Treatment of Stainless Steel Pipe Fittings

Posted: 03/22/2021 10:55:44 Hits: 18For austenitic stainless steel pipe fittings that have not been subjected to solution heat treatment or it is not in accordance with the solution process before leaving the factory, the inspector can't know whether they are well treated based on the appearance on site. The principle of... -

Standard Classification and Use of Carbon Steel Elbow

Posted: 07/02/2020 05:27:59 Hits: 63Carbon steel elbows are metal fittings that change the direction of carbon steel pipelines. The connection method includes screw and welding. According to the angle, there are three kinds of the most commonly used, 45°, 90°and 180°. In addition, according to the needs of the project, it... -

A brief introduction to pipe tee, the most common pipe fitting

Posted: 05/28/2020 01:04:32 Hits: 410A pipe connection with three openings is called a tee. Tees are widely used in the pipe network for conveying liquid and gas. Due to different media, the material of the pipe tee is divided into: cast iron, cast steel, cast copper, cast aluminum, plastic, glass, etc. The application of tees is also... -

How to choose graphite composite gaskets?

Posted: 08/10/2018 11:33:54 Hits: 49A graphite composite gasket is a kind of superior gasket. It is used in many equipment. Its excellent performance is incomparable. It is made of metal tooth plates or metal mesh plates and expanded graphite particles, and it is usually stamped or cut from reinforced graphite sheets by professional gasket... -

Knowledge of a spiral wound gasket

Posted: 05/29/2018 03:37:23 Hits: 54A spiral wound gasket is one of the most widely used gaskets currently. A spiral wound gasket comprises a mix of metallic and filler material. A gasket has a metal wound outwards in a circular spiral with the filler material (generally a flexible graphite) wound in the same manner... -

Do You Install Gaskets Correctly?

Posted: 11/27/2017 09:12:48 Hits: 36Gaskets are very common spare parts for equipment. Do you install gaskets correctly? If they are not installed correctly, they will be damaged or there will even be danger when the equipment is running. What tools should we prepare before installing a gasket? The tools we should prepare: Calibrated... -

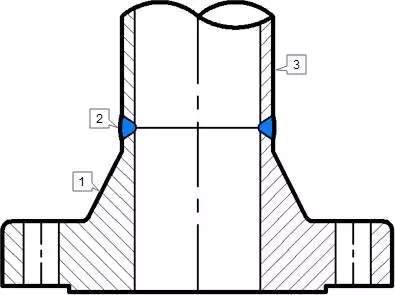

The Differences between Socket Welding and Butt Welding

Posted: 11/14/2017 09:40:07 Hits: 655Socket Welding Socket welding, just as its name implies, is socket welding in the pipeline which forms angle welding. 1. Socket welded flanges 2. Welding seams 3. Pipelines X equals gaps of welding seams Socket welding is usually used for welding pipes with small diameters. The common specifications... -

Applications of Eight Different Gaskets (Part Four)

Posted: 10/13/2017 02:35:33 Hits: 225. Spiral Wound Gaskets Spiral wound gaskets skillfully take advantage of heat resistance, elastic resilience and strength of metal as well as flexibility of nonmetal materials. Therefore, spiral wound gaskets have good sealing performance, and stainless steel flexible graphite spiral wound gaskets... -

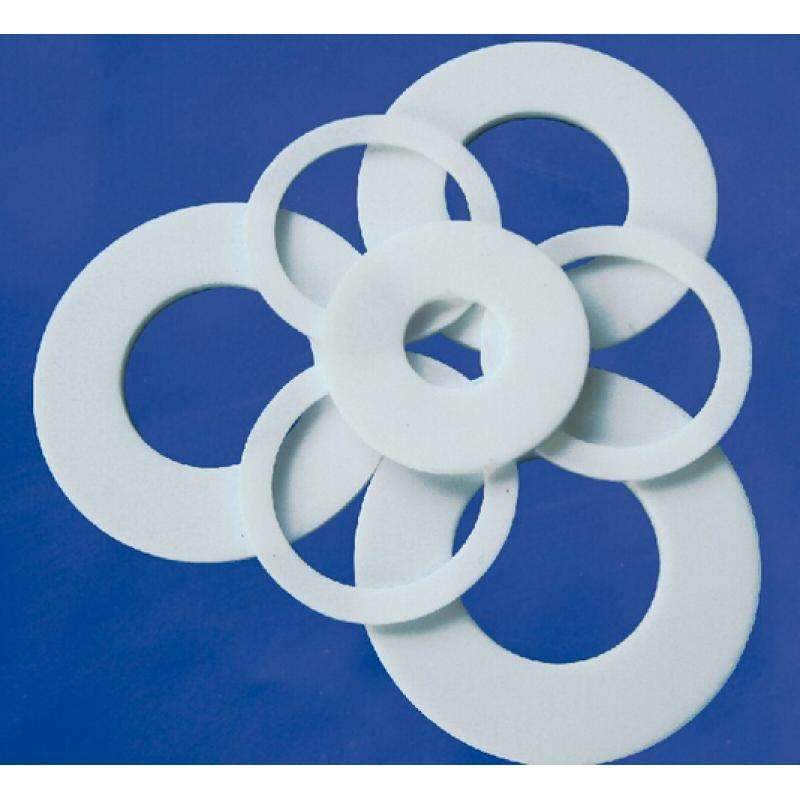

Applications of Eight Different Gaskets (Part Three)

Posted: 09/27/2017 04:36:42 Hits: 333. PTFE (polytetrafluoroethylene) gaskets Cold flows and creeps will easily happen in PTFE gaskets at pressure and high temperature. Therefore, PTFE gaskets are usually applied to low-pressure, medium temperature, strong corrosive and uncontaminated media such as strong acid, alkali, halogen and drugs....