The Analysis of Stress of Pipe Fittings

Posted: 11/15/2023 02:12:54 Hits: 111

1.1 Elbows

Elbows are mainly used to change the direction of pipes. There are two manufacturing and forming processes: one is the medium-frequency induction heating pushing process of steel pipe and the other is the press forming process of the steel pipe. There are differences between the two processes of manufacturing elbows adopted by domestic and foreign pipe fitting companies. For elbows with DN less than and equal to 600mm, the medium-frequency induction heating pushing process is used, while the press forming process is adopted for elbows with DN greater than 600mm. Pipe fitting companys do not differentiate according to the elbow’s diameter. Elbows with DN less than and equal to 700mm can be made by one of the two processes mentioned above and DN greater than 700mm can be made by the steel plate press forming process. These two manufacturing processes have different changes in the wall thickness of the elbow after forming. Generally, medium-frequency induction heating pushing makes the outer arc side wall thickness of the elbow thinner, and the inner arc side wall thickness increases significantly; the inner and outer arc side wall thickness of the elbow made by the steel plate press forming process does not change much, and the wall thickness of the neutral surface of the elbow does not change. It can be seen that the change in elbow wall thickness is closely related to the bending process.

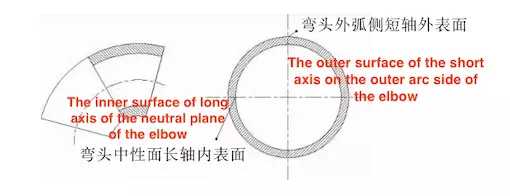

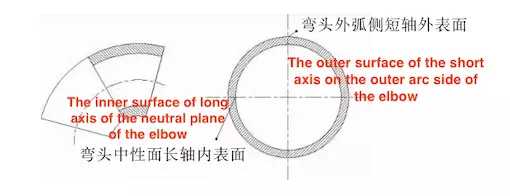

After the elbow bears the internal pressure of the medium, the hoop stress on the inner arc side is greater than that on the outer arc side. The maximum hoop stress is located on the inner arc side. The hoop stress on the neutral plane is equal to that of the straight pipe. The change value of the hoop stress on the inner and outer arc sides of the elbow relative to the hoop stress on the straight pipe is calculated and determined through formulas. The axial stress of the elbow under the action of the internal pressure of the medium is equal to that of the straight pipe and there is no change. In the process of pushing or pressing the elbow, ovality will inevitably occur on its cross section. This ovality will change towards a round shape after the elbow is subjected to the internal pressure of the medium, causing additional bending stress on the elbow wall and the outer surface of the short axis on the outer arc side of the elbow cross section and the inner surface of the long axis on the neutral plane to bear additional stress (Figure 1). This additional stress can also be calculated and determined by the formula.

Figure 1 The section of the elbow

Many blasting tests have confirmed that the cracking point of the elbow formed by the medium-frequency induction heating pushing process in the hydraulic test is near the outer arc side or the neutral surface. However, this does not rule out the use of hot-pressed steel plates to make bends. When the elbow is bent, the cracking point of the elbow's hydrostatic test explosion occurs near the inner arc side, which has been confirmed by examples. To sum up, in the process of pushing or pressing the elbow made from the steel pipe or steel plate, the wall thickness of the elbow changes and the ovality occurs due to the change of the structural shape and the influence of the manufacturing process, causing the hoop stress at different parts of the elbow to change. The parts that should be paid attention to are the inner and outer arc sides and the neutral surface of the elbow. The parts that generate the maximum stress are generally near the outer arc side or the neutral surface of the elbow, but this does not exclude the fact that when the elbow is formed by the steel plate pressing process, the inner arc side will become the danger point of maximum stress.

1.2 Tees

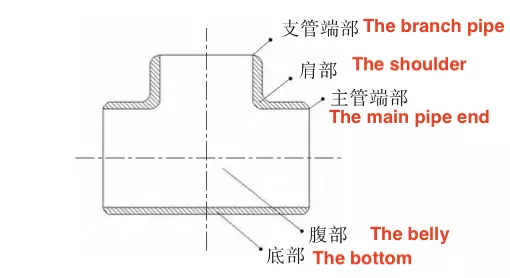

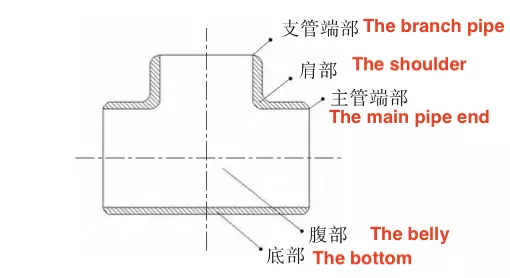

The structure of the hot-molded and drawn tee is shown in Figure 2. The hot-molded drawn tee is made by heating the raw steel pipe multiple times in a heating furnace and then drawing it under the action of a press and a mold. Either a length compensation process or a diameter compensation process for the steel pipe will cause significant changes in the wall thickness. Many pipe fitting companies at home and abroad use the diameter compensation process to manufacture hot-molded and drawn tees. This process makes the wall thickness of the tees’ shoulders and abdomen increase. The rule of change of tee wall thickness is as follows: The wall thickness on the cross-section at the end of the main pipe is variable, with the upper part being the thickest and the bottom being the thinnest. The wall thickness of the upper part is greater than the belly, while the wall thickness of the belly is greater than the bottom. The wall thickness of the cross-section of the branch pipe end is the same. From the end of the branch pipe along the axis of the branch pipe and main pipe through the shoulder to the end of the main pipe, the wall thickness changes, and the thickness gradually increases. The wall thickness at the end of the branch pipe is the smallest, and the wall thickness at the end of the main pipe is the greatest. The wall thickness of the bottom of the main pipe along the axial direction of the main pipe does not change much; the wall thickness of the belly of the main pipe is greater than that of the raw steel pipe; the wall thickness of each part of the main pipe and branch pipe of tees changes greatly and is more complicated than that of the raw steel pipe. From this, it can be concluded that the hot-molded and drawn tee is a special-shaped component with variable wall thickness, and it is difficult to calculate its stress using accurate theoretical analysis.

Figure 2 Structural diagram of hot molded and drawn tees

Under the action of the internal pressure of the medium, the maximum stress zone of the hot-molded and drawn tee is located at the inner arc of the shoulder of the tee, and the second stress zone is located at the outer wall of the abdomen. This is because under the action of the internal pressure of the medium, in addition to bearing the film stress, additional bending moments are produced at the shoulder due to structural shape changes, resulting in additional bending stress at the shoulder. The superposition of the two makes the shoulder become the maximum stress area of the tee. A reasonable inner and outer wall arc diameter of the tee shoulder can effectively improve the stress concentration at the arc of the inner wall of the shoulder; the tee belly becomes another high stress concentration area due to changes in wall thickness; the blasting results of the tee hydraulic test done on many large domestic gas pipeline projects show that the bursting point of a tee under pressure is mostly located on the shoulder of the tee.

The blasting results of high-pressure and large-diameter tee hydraulic tests have repeatedly proven the following arguments: First, the shoulder of the tee is not the thinnest part, but the stress concentration caused by changes in its structural shape makes the shoulder the area with the greatest stress in the tee. This is the most dangerous part of the tee stress; second, the decisive area to determine whether the tee is safe should be its shoulder. The wall thickness of the shoulder is the key data that determines the safe operation of the tee under internal pressure, so the designed wall thickness of the tee should be determined by the wall thickness of the shoulder.

Elbows are mainly used to change the direction of pipes. There are two manufacturing and forming processes: one is the medium-frequency induction heating pushing process of steel pipe and the other is the press forming process of the steel pipe. There are differences between the two processes of manufacturing elbows adopted by domestic and foreign pipe fitting companies. For elbows with DN less than and equal to 600mm, the medium-frequency induction heating pushing process is used, while the press forming process is adopted for elbows with DN greater than 600mm. Pipe fitting companys do not differentiate according to the elbow’s diameter. Elbows with DN less than and equal to 700mm can be made by one of the two processes mentioned above and DN greater than 700mm can be made by the steel plate press forming process. These two manufacturing processes have different changes in the wall thickness of the elbow after forming. Generally, medium-frequency induction heating pushing makes the outer arc side wall thickness of the elbow thinner, and the inner arc side wall thickness increases significantly; the inner and outer arc side wall thickness of the elbow made by the steel plate press forming process does not change much, and the wall thickness of the neutral surface of the elbow does not change. It can be seen that the change in elbow wall thickness is closely related to the bending process.

After the elbow bears the internal pressure of the medium, the hoop stress on the inner arc side is greater than that on the outer arc side. The maximum hoop stress is located on the inner arc side. The hoop stress on the neutral plane is equal to that of the straight pipe. The change value of the hoop stress on the inner and outer arc sides of the elbow relative to the hoop stress on the straight pipe is calculated and determined through formulas. The axial stress of the elbow under the action of the internal pressure of the medium is equal to that of the straight pipe and there is no change. In the process of pushing or pressing the elbow, ovality will inevitably occur on its cross section. This ovality will change towards a round shape after the elbow is subjected to the internal pressure of the medium, causing additional bending stress on the elbow wall and the outer surface of the short axis on the outer arc side of the elbow cross section and the inner surface of the long axis on the neutral plane to bear additional stress (Figure 1). This additional stress can also be calculated and determined by the formula.

Figure 1 The section of the elbow

Many blasting tests have confirmed that the cracking point of the elbow formed by the medium-frequency induction heating pushing process in the hydraulic test is near the outer arc side or the neutral surface. However, this does not rule out the use of hot-pressed steel plates to make bends. When the elbow is bent, the cracking point of the elbow's hydrostatic test explosion occurs near the inner arc side, which has been confirmed by examples. To sum up, in the process of pushing or pressing the elbow made from the steel pipe or steel plate, the wall thickness of the elbow changes and the ovality occurs due to the change of the structural shape and the influence of the manufacturing process, causing the hoop stress at different parts of the elbow to change. The parts that should be paid attention to are the inner and outer arc sides and the neutral surface of the elbow. The parts that generate the maximum stress are generally near the outer arc side or the neutral surface of the elbow, but this does not exclude the fact that when the elbow is formed by the steel plate pressing process, the inner arc side will become the danger point of maximum stress.

1.2 Tees

The structure of the hot-molded and drawn tee is shown in Figure 2. The hot-molded drawn tee is made by heating the raw steel pipe multiple times in a heating furnace and then drawing it under the action of a press and a mold. Either a length compensation process or a diameter compensation process for the steel pipe will cause significant changes in the wall thickness. Many pipe fitting companies at home and abroad use the diameter compensation process to manufacture hot-molded and drawn tees. This process makes the wall thickness of the tees’ shoulders and abdomen increase. The rule of change of tee wall thickness is as follows: The wall thickness on the cross-section at the end of the main pipe is variable, with the upper part being the thickest and the bottom being the thinnest. The wall thickness of the upper part is greater than the belly, while the wall thickness of the belly is greater than the bottom. The wall thickness of the cross-section of the branch pipe end is the same. From the end of the branch pipe along the axis of the branch pipe and main pipe through the shoulder to the end of the main pipe, the wall thickness changes, and the thickness gradually increases. The wall thickness at the end of the branch pipe is the smallest, and the wall thickness at the end of the main pipe is the greatest. The wall thickness of the bottom of the main pipe along the axial direction of the main pipe does not change much; the wall thickness of the belly of the main pipe is greater than that of the raw steel pipe; the wall thickness of each part of the main pipe and branch pipe of tees changes greatly and is more complicated than that of the raw steel pipe. From this, it can be concluded that the hot-molded and drawn tee is a special-shaped component with variable wall thickness, and it is difficult to calculate its stress using accurate theoretical analysis.

Figure 2 Structural diagram of hot molded and drawn tees

Under the action of the internal pressure of the medium, the maximum stress zone of the hot-molded and drawn tee is located at the inner arc of the shoulder of the tee, and the second stress zone is located at the outer wall of the abdomen. This is because under the action of the internal pressure of the medium, in addition to bearing the film stress, additional bending moments are produced at the shoulder due to structural shape changes, resulting in additional bending stress at the shoulder. The superposition of the two makes the shoulder become the maximum stress area of the tee. A reasonable inner and outer wall arc diameter of the tee shoulder can effectively improve the stress concentration at the arc of the inner wall of the shoulder; the tee belly becomes another high stress concentration area due to changes in wall thickness; the blasting results of the tee hydraulic test done on many large domestic gas pipeline projects show that the bursting point of a tee under pressure is mostly located on the shoulder of the tee.

The blasting results of high-pressure and large-diameter tee hydraulic tests have repeatedly proven the following arguments: First, the shoulder of the tee is not the thinnest part, but the stress concentration caused by changes in its structural shape makes the shoulder the area with the greatest stress in the tee. This is the most dangerous part of the tee stress; second, the decisive area to determine whether the tee is safe should be its shoulder. The wall thickness of the shoulder is the key data that determines the safe operation of the tee under internal pressure, so the designed wall thickness of the tee should be determined by the wall thickness of the shoulder.

Post URL: https://www.landeepipefitting.com/the-analysis-of-stress-of-pipe-fittings.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Stainless Steel Tees

Next: Cracking of Welding Seams of Eccentric Reducers in Ultra-high Pressure Steam Pipelines (Part One)

Next: Cracking of Welding Seams of Eccentric Reducers in Ultra-high Pressure Steam Pipelines (Part One)