The Forming of the Reducing Tee

Posted: 08/22/2022 03:30:27 Hits: 93

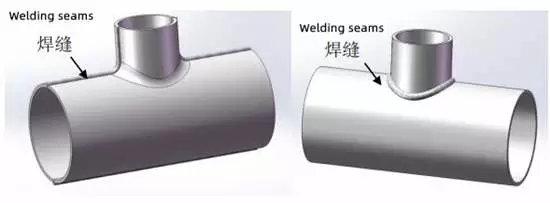

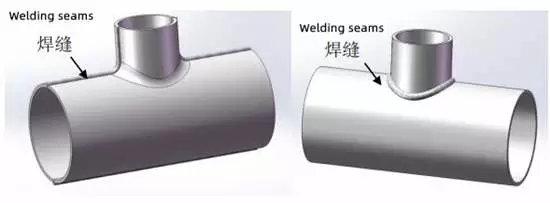

Nowadays, with the rapid development of aviation enterprises, there are many applications of tee fittings to the system of aircraft. In traditional applications, the butt welding process or fillet welding process is used for forming the tee, as shown in Figure 1. Figure (a) is a butt welding that welds two workpieces simultaneously along the entire end face, and Figure (b) is a fillet weld where two mutually perpendicular weld faces are welded together. The main problems of these two welding processes are: (1) The reliability and strength of the welded tee are deteriorated due to the presence of welding seams and residual stress in the welded tee. (2) The inner surface of the welded tee is not smooth enough, causing the resistance of the fluid in the cavity to increase. The hydraulic integral forming technology of the tee can improve the above defects and the overall quality of the tee.

In the early 1980s, there were a large number of experts and scholars abroad, who used different methods to study the relationship between the defect form and the loading path in the internal high-pressure forming, using the relationship between the forming interval and distribution of wall thickness, coupled with the research on the performance test of the pipe to explore basic theoretical issues such as friction behavior under high pressure and preform optimization. Yanbo Li, Rongfeng Liu and others from the Institute of Industrial Technology of the Chinese Academy of Sciences in Guangzhou can use JSTAMP/NV to simulate the hydroforming process of the pipe very effectively, and can predict the defects such as buckling, wrinkling and cracking in the deformation area in the forming process, which can guide actual forming.

The reducing tee is unilaterally formed pipes in terms of structure. The important indicators to measure the technical level and difficulties of such pipe fittings are expansion rates. The expansion rate refers to the rate of change from the circumference of the original pipe to the maximum section circumference of the formed part, which is mainly related to the material properties of the part, the length of the deformation zone, the lubrication method and the loading path. Under these numerous influencing factors, simply using experiments to verify will result in considerable loss of manpower and material resources. The method of using numerical simulation to obtain beneficial process parameters can reduce the consumption of manpower and material resources and the number of tests. With the progress of the times, it is a high potential and reliable method.

(a) Butt welding (b) Fillet welding

Figure 1 Two welding processes

Forming principles and processes of reducing tees

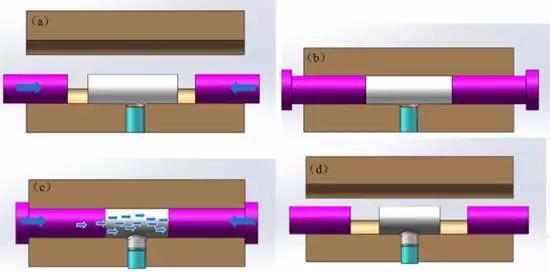

The forming principle of the reducing tee is similar to that of the ordinary tee. Pressurize the inside of the sealed tube blank, and at the same time use the pusher feed force to press the tube blank into the cavity of the mold branch to make the required reducing tee. The radius of the branch pipe of the forming die is smaller than that of the straight pipe, and the forming process is shown in Figure 2.

Figure 2 The schematic diagram of forming reducing tees

As shown in Figure 2(a), first, after removing the burrs from the pipe blank, clean it and use the corresponding lubricant; put it into the mold cavity. Second, the mold is closed, and the punch is fed axially to make both ends of the pipe fittings move toward the center; the punches are rigidly contacted and sealed with both ends of the pipe fittings, as shown in Figure 2(b). Third, use the low-pressure pump to fill the forming system of the tee with liquid. Fill the tube blank with liquid. Empty the air in the tube blank cavity, and then use the feed of the punch and the internal pressure in the cavity to work together, as shown in Figure 2(c). Fourth, the intelligent circuit through the pressure sensor is used to control the booster cylinder and the high-pressure resistant relief valve, so that the internal pressure of the pipe reaches the set value, and the pressure of the top cylinder of the branch pipe is controlled; the pipe fittings are deformed, and the parts are finally formed. The cylinder ejects the parts, as shown in Figure 2(d). In the forming process, a high-pressure relief valve is used, and its purpose is to control the forming pressure of the equipment and prevent the instability of the equipment from causing excessive forming. When the pressure reaches the overflow pressure value, the pressure medium will be released to prevent the rupture of the pipe fitting due to excessive pressure. Compared with forming of the equal tee, when the reducing tee is formed, the diameter-thickness ratio of the pipe part of the branch pipe is reduced due to the reduction of the diameter of the branch pipe and the wall thickness of the tube embryo, and the top cylinder of the branch pipe can be omitted.

The reduced tee is formed entirely by the force generated by the internal pressure of the tube. In the forming process of the reducing tee, because the diameter of the branch pipe is smaller than that of the equal tee, the pressure of the branch pipe is greater than that of the equal tee under the same internal pressure during forming.

In the early 1980s, there were a large number of experts and scholars abroad, who used different methods to study the relationship between the defect form and the loading path in the internal high-pressure forming, using the relationship between the forming interval and distribution of wall thickness, coupled with the research on the performance test of the pipe to explore basic theoretical issues such as friction behavior under high pressure and preform optimization. Yanbo Li, Rongfeng Liu and others from the Institute of Industrial Technology of the Chinese Academy of Sciences in Guangzhou can use JSTAMP/NV to simulate the hydroforming process of the pipe very effectively, and can predict the defects such as buckling, wrinkling and cracking in the deformation area in the forming process, which can guide actual forming.

The reducing tee is unilaterally formed pipes in terms of structure. The important indicators to measure the technical level and difficulties of such pipe fittings are expansion rates. The expansion rate refers to the rate of change from the circumference of the original pipe to the maximum section circumference of the formed part, which is mainly related to the material properties of the part, the length of the deformation zone, the lubrication method and the loading path. Under these numerous influencing factors, simply using experiments to verify will result in considerable loss of manpower and material resources. The method of using numerical simulation to obtain beneficial process parameters can reduce the consumption of manpower and material resources and the number of tests. With the progress of the times, it is a high potential and reliable method.

(a) Butt welding (b) Fillet welding

Figure 1 Two welding processes

Forming principles and processes of reducing tees

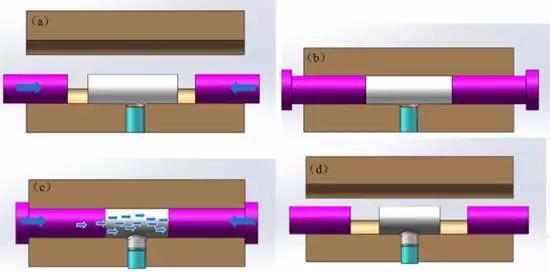

The forming principle of the reducing tee is similar to that of the ordinary tee. Pressurize the inside of the sealed tube blank, and at the same time use the pusher feed force to press the tube blank into the cavity of the mold branch to make the required reducing tee. The radius of the branch pipe of the forming die is smaller than that of the straight pipe, and the forming process is shown in Figure 2.

Figure 2 The schematic diagram of forming reducing tees

As shown in Figure 2(a), first, after removing the burrs from the pipe blank, clean it and use the corresponding lubricant; put it into the mold cavity. Second, the mold is closed, and the punch is fed axially to make both ends of the pipe fittings move toward the center; the punches are rigidly contacted and sealed with both ends of the pipe fittings, as shown in Figure 2(b). Third, use the low-pressure pump to fill the forming system of the tee with liquid. Fill the tube blank with liquid. Empty the air in the tube blank cavity, and then use the feed of the punch and the internal pressure in the cavity to work together, as shown in Figure 2(c). Fourth, the intelligent circuit through the pressure sensor is used to control the booster cylinder and the high-pressure resistant relief valve, so that the internal pressure of the pipe reaches the set value, and the pressure of the top cylinder of the branch pipe is controlled; the pipe fittings are deformed, and the parts are finally formed. The cylinder ejects the parts, as shown in Figure 2(d). In the forming process, a high-pressure relief valve is used, and its purpose is to control the forming pressure of the equipment and prevent the instability of the equipment from causing excessive forming. When the pressure reaches the overflow pressure value, the pressure medium will be released to prevent the rupture of the pipe fitting due to excessive pressure. Compared with forming of the equal tee, when the reducing tee is formed, the diameter-thickness ratio of the pipe part of the branch pipe is reduced due to the reduction of the diameter of the branch pipe and the wall thickness of the tube embryo, and the top cylinder of the branch pipe can be omitted.

The reduced tee is formed entirely by the force generated by the internal pressure of the tube. In the forming process of the reducing tee, because the diameter of the branch pipe is smaller than that of the equal tee, the pressure of the branch pipe is greater than that of the equal tee under the same internal pressure during forming.

Post URL: https://www.landeepipefitting.com/the-forming-of-the-reducing-tee.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.