The Role and Advantages of Reducing Tees in Piping Systems

Posted: 02/24/2024 03:05:38 Hits: 100

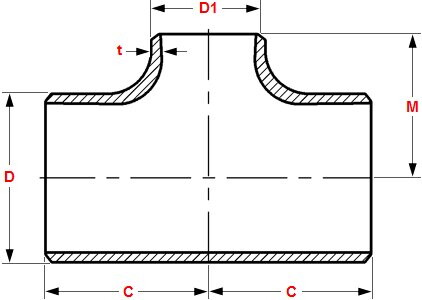

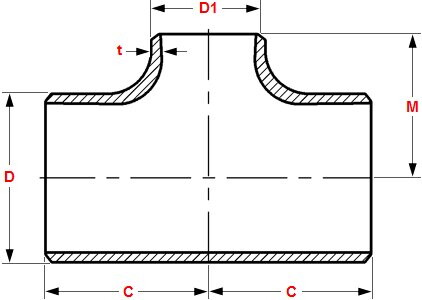

A reducing tee, a crucial component in piping systems, is ingeniously designed to connect pipes of varying diameters, exhibiting outstanding performance when linking dissimilar pipe sizes. Apart from facilitating smooth fluid redirection, it serves multiple functions within a piping network. Let's delve deeper into the advantages and functions of reducing tees to highlight their significance and extensive application prospects in pipeline engineering.

Advantages of Reducing Tees

The advantages of a reducing tee in piping systems are numerous and impactful, making it a preferred choice for various applications. Here are some key advantages:

Functions of Reducing Tees

The reducing tee is a fundamental component in piping systems, serving several important functions that contribute to the overall efficiency and effectiveness of fluid transportation. Here are the key functions of a reducing tee:

Advantages of Reducing Tees

The advantages of a reducing tee in piping systems are numerous and impactful, making it a preferred choice for various applications. Here are some key advantages:

1. High Flexibility

The defining feature of a reducing tee lies in its flexible connectivity. It adeptly joins pipes of different diameters, ensuring fluid redirection with seamless precision. This flexibility enhances the adjustability of the pipeline system while effectively reducing fluid resistance during transportation.

2. Space Efficiency

By amalgamating pipes of varying diameters, reducing tees excel in space utilization. They minimize the footprint of pipe connections, making them particularly suitable for confined spaces such as factories and vessels.

3. Reduced Pipeline Resistance

Carefully crafted, reducing tees facilitate fluid flow redirection without abrupt changes in direction, thereby diminishing pipeline resistance. This design optimization enhances system stability and reliability, especially in demanding engineering fields like hydraulic transmission systems.

4. Adaptability to Varying Flow Rates

In fluid transmission processes, the need to adjust flow rates to meet diverse requirements arises. Reducing tees enable flow regulation and control between two pipes of different diameters, flexibly catering to various operational scenarios, thus ensuring efficient and safe fluid transmission.

5. Noise and Vibration Reduction

In pipeline systems, water flow noise and vibrations often pose challenges, especially during long-distance fluid conveyance. By minimizing abrupt changes in fluid direction, reducing tees effectively mitigate pipeline noise and vibration, thereby enhancing workplace comfort and safety.

The defining feature of a reducing tee lies in its flexible connectivity. It adeptly joins pipes of different diameters, ensuring fluid redirection with seamless precision. This flexibility enhances the adjustability of the pipeline system while effectively reducing fluid resistance during transportation.

2. Space Efficiency

By amalgamating pipes of varying diameters, reducing tees excel in space utilization. They minimize the footprint of pipe connections, making them particularly suitable for confined spaces such as factories and vessels.

3. Reduced Pipeline Resistance

Carefully crafted, reducing tees facilitate fluid flow redirection without abrupt changes in direction, thereby diminishing pipeline resistance. This design optimization enhances system stability and reliability, especially in demanding engineering fields like hydraulic transmission systems.

4. Adaptability to Varying Flow Rates

In fluid transmission processes, the need to adjust flow rates to meet diverse requirements arises. Reducing tees enable flow regulation and control between two pipes of different diameters, flexibly catering to various operational scenarios, thus ensuring efficient and safe fluid transmission.

5. Noise and Vibration Reduction

In pipeline systems, water flow noise and vibrations often pose challenges, especially during long-distance fluid conveyance. By minimizing abrupt changes in fluid direction, reducing tees effectively mitigate pipeline noise and vibration, thereby enhancing workplace comfort and safety.

Functions of Reducing Tees

The reducing tee is a fundamental component in piping systems, serving several important functions that contribute to the overall efficiency and effectiveness of fluid transportation. Here are the key functions of a reducing tee:

1. Pipe Connection: As a vital piping component, reducing tees primarily serve to connect pipes of different diameters, facilitating fluid redirection and transmission.

2. Flow Rate Adjustment: Within pipeline systems, reducing tees enable the adjustment of fluid flow rates as per requirements, ensuring stability and efficiency in fluid transmission.

3. Pipeline Redirection: Reducing tees facilitate pipeline redirection, accommodating specific pipeline system layouts and operational requirements.

4. Branch Pipeline Addition: By strategically configuring reducing tees, additional branches can be incorporated into the pipeline system, meeting fluid transmission needs in different operational areas.

5. Cost Reduction in Operations: The judicious application of reducing tees can lower the operational costs of pipeline systems, enhancing system efficiency and reliability, thereby reducing associated maintenance and repair expenses.

In practical applications, the importance of reducing tees as piping components is self-evident. Their advantages, including high flexibility, space efficiency, low resistance, and reduced noise, underscore their pivotal role in enhancing the efficiency and stability of pipeline systems while lowering operational costs. Consequently, reducing tees have found widespread applications and endorsements in various sectors such as industry, construction, and energy.2. Flow Rate Adjustment: Within pipeline systems, reducing tees enable the adjustment of fluid flow rates as per requirements, ensuring stability and efficiency in fluid transmission.

3. Pipeline Redirection: Reducing tees facilitate pipeline redirection, accommodating specific pipeline system layouts and operational requirements.

4. Branch Pipeline Addition: By strategically configuring reducing tees, additional branches can be incorporated into the pipeline system, meeting fluid transmission needs in different operational areas.

5. Cost Reduction in Operations: The judicious application of reducing tees can lower the operational costs of pipeline systems, enhancing system efficiency and reliability, thereby reducing associated maintenance and repair expenses.

Post URL: https://www.landeepipefitting.com/the-role-and-advantages-of-reducing-tees-in-piping-systems.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Tips for Enhancing Stability of Welded Pipe Elbows

Next: Gasket Sealing: Mechanisms and Leak Prevention in Industry

Next: Gasket Sealing: Mechanisms and Leak Prevention in Industry